Aluminum electrolytic cell is the main thermal equipment for aluminum electrolysis production. Electrolytic aluminum is the process of converting aluminum in alumina into metallic aluminum. There is an outstanding problem in the aluminum electrolytic plant. The bottom of the tank is cold. Improvement measures include blocking the windows in the lower part of the two-story structure, laying bricks within the tank shell frame, and coating the outside of the tank with an insulation layer.

Aluminum electrolytic cells are divided into bottom type and bottomless type according to the structure of the tank. According to the shape of the tank shell, it is divided into square and rectangular. According to the anode structure, it is divided into a prebaked anode and a continuous self-baked anode. According to the conductive mode, it is divided into side conductive and upper conductive.

The lining materials used in aluminum electrolytic cell-related equipment include calcium silicate boards, clay-insulating refractory bricks, clay refractory bricks, and dry anti-seepage materials. Cathode carbon block, carbon paste, water glass asbestos putty, silicon nitride silicon carbide thermal insulation coating, etc. The heat insulation layer refractory material can be placed between the tank bottom and the asbestos board to increase the heat insulation. The thermal insulation performance is more than five times stronger than calcium silicate boards of the same thickness.

High-Temperature Thermal Insulation Coating for Aluminum Electrolytic Cells

High-temperature thermal insulation coating is processed from specially synthesized inorganic silicate solution, aluminum silicate fiber, heat-reflective material, and selected hollow ceramic beads. Water-based, environmentally friendly, non-toxic, and harmless. The characteristics of high-temperature thermal insulation coating products for aluminum electrolytic cells are as follows:

- Thermos bottle thermal insulation mechanism.

- The hollow ceramic beads in the coating greatly reduce heat convection.

- Inorganic film-forming substances with relatively low thermal conductivity.

- Sound insulation and noise reduction, fire-retardant, wear-resistant and pressure-resistant, insulation-resistant and puncture-resistant, acid and alkali-resistant, lightweight, easy construction, and long service life.

The curing principle of high-temperature thermal insulation coating for aluminum electrolytic cells:

Silicate coatings are composed of a variety of silicates and a small amount of organic and inorganic binders. Its curing principle: a special silicate solution acts as a gelling agent. Aggregation process:

- The condensation of silanol and the condensation between silanol and the aluminum hydroxyl group of the silicate. Form a three-dimensional skeleton network.

- Silicates are polymerized according to layered and framework molecular-level silicone groups. The mixed metal oxide acts as a space filler between the three-dimensional skeleton of the main body.

Application of High-Temperature Thermal Insulation Coating

- Surface painting. High-temperature molds and outer surfaces of injection molding machines. On the inner surface of high-temperature flues and exhaust pipes. Paint the thermal insulation surface of hot water tanks and dye vats.

- Ceramic production, ceramic roller kiln, refractory rotary kiln. Cement plant applications, cement rotary kiln, preheater, decomposition furnace.

- Steel plant applications, ring furnaces, heating furnaces, and quenching furnaces. Molten steel tundish. Blast furnace workshop steel structure insulation, coke oven.

- The inner wall of the furnace shell of the smelting furnace in the metallurgical copper industry. The inner wall of the electrolytic aluminum furnace (aluminum industry).

- The outer surface of the power plant turbine shell/shaft seal; and the outer surface of the steam pipe are painted. Petrochemical heating furnace, vacuum heating furnace, cracking furnace.

- The top of the boiling furnace is insulated and sealed. Industrial heating furnace. Vacuum furnace insulation.

- Driving cab (Crane Crane). Explosion-proof vehicles, asphalt vehicles, engineering vehicles, and military armored vehicle chassis.

- Spinning box, high-temperature oven surface. New energy batteries and intermediate frequency furnaces.

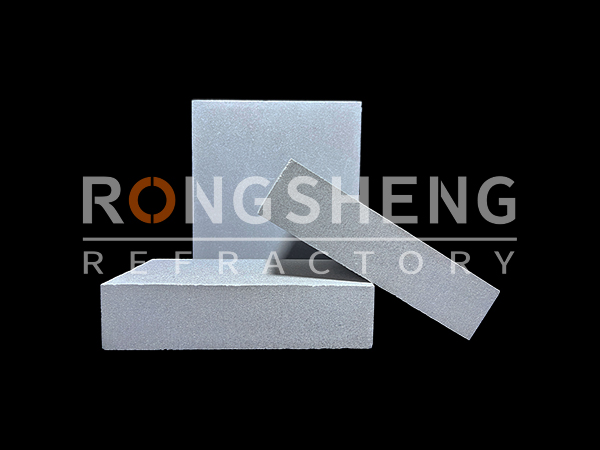

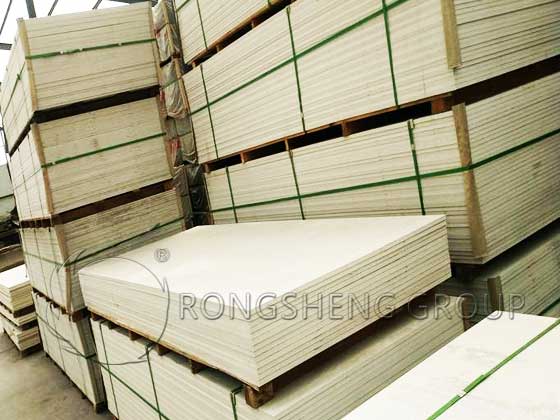

Calcium Silicate Board for Aluminum Electrolytic Cell

Calcium silicate board is a new type of building material, also called “calcium silicate board”, “calcium magnesium silicate board”, “MgO board”, etc. It is a composite building material made of a variety of materials and has multiple functions such as fire protection, waterproofing, sound insulation, heat preservation, and corrosion resistance. Calcium silicate boards can be widely used in various fields such as building walls, roofs, partitions, and floors. It has high economic and social benefits.

The main components of calcium silicate board are inorganic mineral fibers as reinforcing materials, and siliceous, calcium, and other materials as the main materials. These materials are made by high-temperature pressing after certain stabilization treatments. Calcium silicate board has good flexural strength, tensile strength, and compressive strength. At the same time, it also has multiple functions such as fire resistance, corrosion resistance, sound insulation, and heat preservation.

Calcium silicate boards also have a wide range of applications and can be used on walls, roofs, partitions, and floors. Calcium silicate board has the characteristics of water resistance, corrosion resistance, etc. Therefore it is widely used in relatively humid places.

Compared with traditional building materials, the installation process of calcium silicate boards is simpler and faster. When installing calcium silicate boards, you only need to install them directly on the frame, and few other materials are used. Therefore, no construction waste and pollutants will be generated. As a thermal insulation material, calcium silicate boards are also widely used in aluminum electrolytic cells.