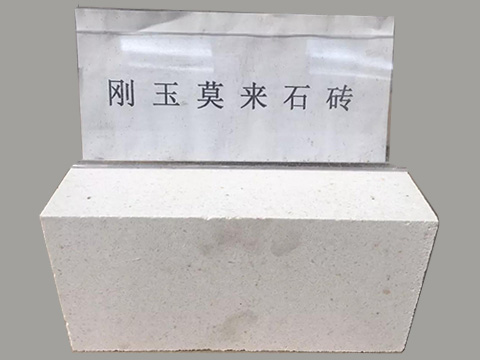

The Carbon Baking Furnaces adopt silicon-alumina refractory materials as a whole. Refractories for Carbon Baking Furnaces. The furnace body of the Carbon Baking Furnace is made of high-quality fire clay bricks or high alumina bricks, and the furnace cover is integrally prefabricated with high-alumina refractory castables.

The brick piers and pit-faced masonry at the bottom of the closed Carbon Baking Furnaces bear the weight of the upper masonry and calcined products. The masonry of the upper electrode box’s heating wall, firebox and burner are subjected to a high temperature of 1400 ° C. At the same time, during each Furnace’s cycle, it is also affected by temperature changes. Therefore, fire clay bricks with high mechanical strength, high load softening temperature, and good thermal stability are used for masonry. The removable furnace cover can be built with heat-resistant refractory materials.

Refractories for Carbon Baking Furnaces

In the construction of a Carbon Baking Furnace, the following refractory materials are required. For example, fire clay bricks, fire clay insulation refractory bricks, special-shaped fire clay bricks, clay refractory mortar, fire clay insulation refractory particles, refractory fiber felt, asbestos rope, fire hole, burner bricks, etc. Among them, the amount of fire clay bricks are the largest.

Fire clay bricks are one of the main varieties of aluminum silicate products. It is made of clay clinker as aggregate and refractory soft clay as a binder with Al2O3 content of 30% ~ 48%. Clay refractory bricks have the following characteristics:

- The properties of clay refractory bricks products can fluctuate in a large range, which is due to the large fluctuation range of the chemical composition of the product and the difference in the production process. (AL2O3 content fluctuates between 30% and 48%).

- The refractoriness fluctuates between 1580 ~ 1700 ° C;

- Its products have good thermal shock resistance and a large fluctuation range, generally more than 10 times (1100 ° C water cooling);

- Coefficient of linear expansion of fire clay products. The average linear expansion coefficient from 20 to 1300 ° C is (4.5 to 5.8) * 10-6 ° C-1.

Fire clay products are kinds of weakly acidic refractory products, which increase their acidity as the SiO2 content increases. It has a certain erosion resistance to acidic slag, but a poor erosion resistance to alkaline slag. Therefore, clay products are suitable for the refractory lining of the acid slag furnace.

Construction of Refractories for the Carbon Baking Furnaces

When the Carbon Baking Furnace is constructed, the furnace body is built first. The flue and “Π” shaped regulators on both sides are built together. As for the bricklaying of the furnace cover and the outer flue (or flue pipe), it will be carried out after the furnace body is completed, and they can also be constructed along with the furnace body under the conditions allowed by the site.

The masonry construction of refractory materials for Carbon Baking Furnaces is often the key to the safe operation of the entire kiln. Therefore, in the masonry construction of the Carbon Baking Furnaces, it is necessary for the construction personnel to carry out the construction in an orderly, and high-quality manner.

Rongsheng Refractory Bricks Manufacturer

Rongsheng is an experienced refractory bricks manufacturer, Rongsheng’s customers have more than 60 countries and regions around the world. Our technical engineers can customize refractory materials for customers according to their production conditions. For refractory bricks that are used in large quantities, such as fire clay bricks, high alumina bricks, and silica bricks, Rongsheng competes with its peers by quality. For thermal furnaces with harsh production conditions, Rongsheng can customize refractory materials for customers. Last year, RS have customized fused silica bricks for a customer. This is also the first time of us to use such refractory, said by the customer. If you need to buy refractory bricks to build refractory lining. Please contact us and we will reply to you as soon as possible, and perfectly solve the refractory linings’ problems. by RS Kiln Refractories Blog.