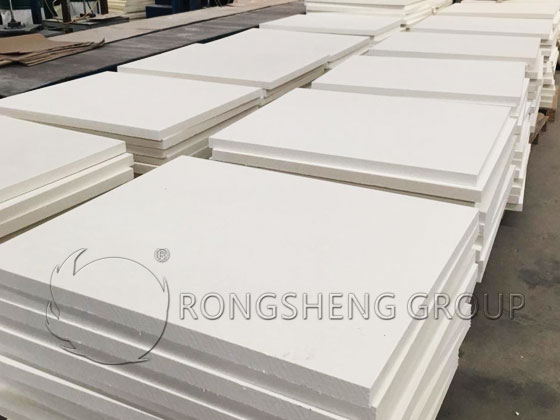

The main raw material of ceramic fiberboard is aluminum silicate, which is one of the important guarantee factors for the kiln to save energy, reduce consumption, and optimize high production. According to the temperature division, fiberboard can be widely used in the backing of industrial kilns or the hot surface of low-temperature kilns. If you want to ask, what advantages does ceramic fiberboard have in industrial furnaces? Then its advantages are still obvious.

- The specific heat capacity (storage heat) is small. One of the reasons why ceramic fiberboard can reduce the maintenance cost of industrial kilns is its small specific heat capacity, which can save energy during the shutdown and start-up of the heating furnace.

- Low thermal conductivity. The ceramic fiberboard furnace lining has low thermal conductivity and a good heat insulation effect.

- Good thermal shock resistance. The porosity of the ceramic fiber board is high, and the ceramic fiber lining can meet various rates of heating or cooling without damage (under the premise that the kiln body can bear it).

- Good sound insulation performance. Ceramic fiber board has good sound insulation ability, can reduce noise pollution, can be used as sound insulation material, and can also be used as wall insulation and sound insulation material in buildings (such as structural insulation integrated ceramic wool composite insulation board).

- Stable chemical properties. The main chemical composition of ceramic fiberboard is aluminum silicate, which does not easy to be corroded except for the reaction with strong acids and alkalis.

- Wide application range. Refractory ceramic fiberboard can meet the requirements of different operating temperature ranges (such as between 600°C and 1300°C). Different industrial furnaces that can be applied to different industries require the use of refractory ceramic fiber boards.

What is the Insulation Effect of Ceramic Fiberboard?

What kind of insulation effect does the ceramic fiber board play? Ceramic fiber board is also called ceramic cotton board, which has good characteristics of high-temperature resistance, heat preservation, and heat insulation, and is widely used. Ceramic fiber boards can be used for the lining of highly heat-sensitive furnaces. So what is the so-called high heat-sensitive stove?

The so-called high heat sensitive furnace means that the furnace can effectively control the heating or cooling speed. In contrast, what is thermal inertia? This means that when the furnace is heated, the heat is almost absorbed by the furnace lining, the furnace temperature is almost synchronized with the furnace wall temperature, and the heat rises slowly. When cooling, almost all the heat is from the furnace wall, and the furnace temperature drops slowly. If the cooling or heating time is too long, it will waste a lot of fuel, and reduce production efficiency and product quality.

The lining material determines how to increase the heat sensitivity of the furnace.

Different from the traditional refractory brick lining, ceramic fiber boards can effectively improve this problem. The ceramic fiber material has a low thermal conductivity and hardly absorbs the heat of the furnace, effectively reducing heat loss and shortening the heating time. When the temperature is lowered, the heat storage capacity of the furnace is reduced, and the heat sensitivity of the furnace is increased.

Application of Ceramic Fiber Products in the Steel Industry

The refractory lining of traditional industrial kilns has a large weight, the waste of heat storage in the furnace body is serious, and the heat preservation effect is poor. The temperature of the cold surface of the furnace body exceeds 100°C, and it is difficult to precisely control the temperature of the furnace. In recent years, the ceramic fiber module refractory lining of the furnace wall and roof of the industrial furnace has been designed with a full fiber lining. Due to the low thermal conductivity, low density, and light weight of fibers, lighter steel frame support structures are used in the design and construction of kilns. As a result, the development of industrial furnaces has entered the era of “kiln lightweight”. The heat storage of fibers is small, which is suitable for the operation mode of rapid heating and cooling. In addition, the ceramic fiber module can be processed into special-shaped products to adapt to various shapes of the inner wall of the furnace shell. The fiber module has good resistance to mechanical vibration and shock and has good chemical stability. These advantages have played an important role in promoting the development of new kilns.

Taking heating furnaces in the steel industry as an example, ceramic fiber modules are mainly used for ladle covers, billet carriers, furnace walls of heat treatment furnaces, etc. At present, a large number of ceramic fiber modules are used as linings in heat treatment furnaces that require high furnace cleanliness. In the annealing furnace for cold-rolled strip steel, from the heating section to the cooling section, from the top to the bottom of the furnace, ceramic fiber modules are used as linings. In the direct fire heating part of the preheating section, the hollow module is convenient for direct installation of the burner. On the furnace wall of the heating section, in order to cooperate with the installation of the radiant tube, the entire furnace wall module adopts the form of B, and at the journal of the furnace roller, the module can be made into a bell shape. Very convenient for furnace lining installation. In order to prevent fiber shedding from polluting the steel strip, aluminum cloth can also be sewn on the module as an inner lining. Special-shaped modules can be used in some special-shaped parts such as the furnace throat and the bottom chamber.

The good thermal insulation performance of the ceramic fiber module makes it widely used in the thermal insulation layer of high-temperature industrial furnaces. RS Kiln Refractory Material Manufacturer is a powerful refractory material manufacturer. Our refractory products have been sold to more than 100 countries and regions all over the world. Moreover, our technical team is committed to the R&D, design, and construction of refractory materials for the insulation layer. Our new thermal insulation material products can achieve a body density of less than 0.4g/cm3. Contact us for free samples and quotes.