Refractory insulation materials are generally used in industrial kilns, metallurgy, pipelines, and thermal equipment to slow down the loss of heat. Most of the refractory insulation materials for the walls of general industrial kilns are made of lightweight refractory insulation materials, such as lightweight clay bricks, lightweight high-alumina bricks, and lightweight refractory castables. Walls have a certain mechanical strength. Where to buy refractory insulation in China? In most cases, an Internet search for “refractory insulation in China” will quickly bring up countless entries. If you want to buy refractory insulation materials economically and economically, we still recommend that you buy them from the manufacturer.

At present, there are various types of furnace-building refractory insulation materials that have been maturely used. Manufacturers of refractory materials generally classify refractory insulation materials according to the standards in the industry. Generally, according to the structure, material and use temperature, etc. Refractory insulation materials can be divided into low-temperature insulation materials (below 600°C), medium-temperature insulation materials (600~1000°C), and high-temperature insulation materials (above 1000°C) according to the use temperature. Combined with many years of production and sales experience, in the selection of thermal insulation lining for high-temperature kilns, there are many kilns that use aluminum silicate fiber refractory thermal insulation materials to save energy.

This is a fact that spread like wildfire. The basic requirements for furnace-building refractory insulation materials are low heat capacity, light bulk density, small thermal conductivity, high strength, and easy construction. The fiber refractory insulation material has its main characteristics of light bulk density, low heat capacity, small thermal conductivity, and easy construction, so it is widely used. For refractory insulation in China, why do most high-temperature industrial furnaces choose fiber refractory insulation materials?

First, the thermal conductivity of fiber refractory insulation materials is low. Thermal conductivity is a very important thermal index of refractory insulation materials. It marks the material’s ability to transfer heat. At the same operating temperature, the thermal conductivity of aluminum silicate refractory fiber is only 1/5 of that of ordinary refractory clay bricks, and less than 1/2 of that of lightweight clay bricks.

Due to the small thermal conductivity of aluminum silicate fiber, using it as a furnace lining or insulation layer can reduce heat loss and save energy compared with commonly used refractory materials. When the volume of the furnace and the temperature inside and outside the furnace wall remain unchanged, the outer surface area of the furnace body can be reduced by about 30% and the heat dissipation loss can be reduced by 15-30% after using aluminum silicate fiber. Therefore, the small thermal conductivity of fiber refractory insulation materials is one of the main reasons for the energy saving of industrial kilns.

Second, the fiber refractory insulation material has a light bulk density. For example, the bulk density of aluminum silicate fiber and its products is 40~220Kg/m³, only less than 20% of light clay bricks, and about 6~8% of ordinary clay bricks. Since the aluminum silicate fiber has a small bulk density and a thinner thickness in use, using it in an industrial furnace can not only reduce the weight of the furnace body but also reduce the heat storage loss of the furnace. Moreover, due to the strong heat storage capacity of the aluminum silicate fiber furnace wall, the temperature rise in the furnace body is fast, which can improve the working efficiency of the kiln. For periodic or discontinuous industrial kilns, using aluminum silicate fiber lining or insulation layer, the energy-saving effect is more significant.

To sum up, fiber refractory insulation materials create good conditions for improving the performance of thermal equipment and are widely used. As long as we choose refractory insulation in China reasonably according to its operating temperature, furnace atmosphere, and other working conditions, we will definitely get good economic benefits.

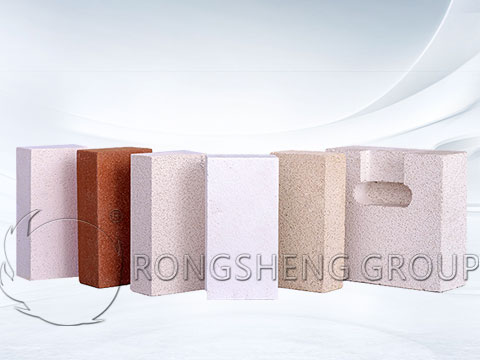

Refractory insulation in China. The refractory insulation material used for high-temperature industrial kiln masonry is a kind of refractory insulation material with high-temperature resistance, low thermal conductivity, and flame retardancy, and can slow down the heat loss caused by heat conduction and heat convection. It slows down heat loss by restricting air heat convection with low thermal conductivity through the special structure of the material. Refractory materials that can realize such functions include refractory insulation bricks, castable refractory insulation, etc. Rongsheng refractory material manufacturer is a manufacturer and sales company of refractory materials in China. Provide you with free samples and quotations. Contact us, to buy refractory insulation in China, to provide the most suitable solution for your kiln insulation.