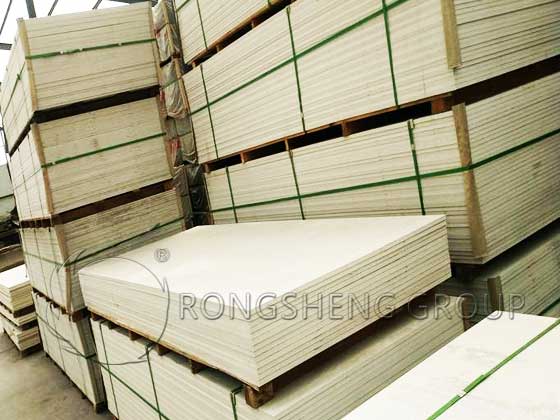

Rongsheng non-asbestos fiber-reinforced calcium silicate board: based on siliceous and calcium materials (tobermorite generated under high temperature and high pressure), fiber-reinforced, must be autoclaved and cured. Fiber-reinforced calcium silicate board is a high-performance, green, and environmentally friendly building material. Its composition, performance and application are as follows:

Composition of Fiber-Reinforced Calcium Silicate Board

- Main materials: Siliceous materials (such as quartz powder, fly ash, diatomaceous earth, rich in SiO₂) and calcium materials (such as lime, calcium carbide mud, cement, rich in CaO) are the main cementing materials.

- Reinforcement materials: Loose short fibers such as inorganic mineral fibers or cellulose fibers are used as reinforcement materials.

- Manufacturing process: Calcium silicate board with mullite (C₅S₆H₅) crystal structure is generated through pulping, molding, high temperature and high pressure steaming and other processes.

Performance of Fiber-Reinforced Calcium Silicate Board

- Fireproof performance: non-combustible A-grade material, does not burn in case of open flame, does not produce toxic smoke, and has a fire resistance limit of more than 90 minutes.

- Waterproof and moisture-proof: stable performance in high humidity environments, not easy to expand or deform, suitable for bathrooms, toilets and other places.

- Strength and durability: high strength, 6mm thick board strength exceeds 9.5mm thick gypsum board, and is not easy to crack or deform.

- Sound insulation and heat insulation: has good sound insulation and heat insulation performance, and the 10mm thick partition wall is better than an ordinary brick wall.

- Environmental protection: non-toxic and harmless, in line with green building materials standards.

Application of Fiber-Reinforced Calcium Silicate Board

- Construction field: used for interior wall panels, exterior wall panels, ceiling panels, curtain wall lining panels, and composite wall panels.

- Industrial field: used as ship bulkhead panels, warehouse shed panels, tunnel siding panels, fireproof ventilation ducts, etc.

Six Outstanding Advantages of Rongsheng Fiber-Reinforced Calcium Silicate Board

- Fireproof and flame retardant: It reaches non-combustible A1 fireproof, flame retardant and heat-insulating, and does not produce any harmful gases.

- Waterproof and corrosion-resistant: Calcium silicate board has super high waterproof and moisture-proof performance, and is also suitable for high temperature and high humidity spaces.

- Super high strength: The strength of 6mm thick calcium silicate board is much greater than that of 9.5mm thick gypsum board, with good wear resistance, not easy to be damaged or cracked, and not easy to deform.

- Super long life: Inorganic material, stable performance, acid and alkali resistance, corrosion resistance, moisture resistance, moth resistance and termite resistance, and mission life is much longer than gypsum board.

- Energy saving and environmental protection: The thermal insulation effect is better than gypsum board, and it can significantly save energy when used in construction. Good sound insulation effect, no dust, asbestos, formaldehyde, etc., to achieve zero environmental pollution.

- Strong decorative effect: The material performance is stable, the temperature deformation is small, the decorative surface style is diverse, it can be customized, fashionable and beautiful.

The material properties of Rongsheng’s asbestos-free reinforced calcium silicate board are determined by chemical reactions (silicon calcium generates tobermorite at high temperatures). Its curing process must be autoclaved. Physical properties: lightweight, good insulation, and resistance to high-temperature deformation. Main uses: indoor fireproof partitions, suspended ceilings, etc. Advantages: Class A fireproof, water-resistant, and moisture-proof, environmentally friendly, and safe.

Calcium silicate board is more suitable for indoor fireproof and heat insulation scenarios. The key to choosing the right board is the application environment and performance requirements! Contact Rongsheng for free samples and quotes.