Corundum Mullite Bricks refer to high alumina refractory bricks composed of corundum and mullite main crystal phases. Corundum Mullite Brick refers to refractory products made of high-purity or relatively pure raw materials. Rongsheng Kiln Refractory Manufacturer provides customers with high-quality refractory bricks. Get a quick quote.

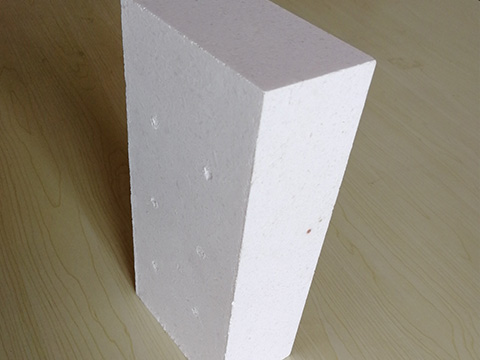

Corundum Mullite Bricks

Corundum mullite bricks are made of corundum and mullite as the main raw materials, and by adding appropriate amounts of alumina, silica ultrafine powder and additives, and firing at high temperature in an oxidizing atmosphere. This refractory bricks’ AL2O3 content is 72% ~ 90%.

Corundum Mullite Brick Features

- Low thermal conductivity, low heat capacity, low impurity content;

- High strength, good thermal shock resistance, anti-corrosion;

- High dimensional accuracy.

Production Process of Corundum Mullite Bricks

The corundum mullite bricks green body was formed by a 300t friction press, and the green body density was 2.7 g / cm3. The green body is dried in a tunnel dryer. The inlet temperature is 40 ~ 50 ℃, the maximum drying temperature is 130 ℃, the drying time is 48h, and the moisture of the green body is not more than 1.5%. The product is fired in a tunnel kiln with a firing temperature of 1550 ° C and a holding time of 10 hours.

Method for Forming Corundum Mullite Brick

(1) Refractory products with complex shapes and large sizes are beaten with air hammer or formed by vibration.

(2) Semi-dry high-pressure molding can be used for ordinary products or standard specifications.

(3) Special-shaped pure or special products need to design molds and adopt isostatic pressing.

Physical Properties of Corundum Mullite Bricks

The high-temperature main crystal phases of corundum mullite bricks are corundum and mullite. The crystals of corundum are short columnar and barrel-shaped, and they are not interspersed or staggered in the refractory structure. Mullite staggered columnar crystals are embedded between the corundum crystals, effectively preventing the corundum crystals from slipping and obtaining a stable structure. Because the crystal structure is more stable, it is more conducive to the excellent properties of mullite or mullite and corundum. Improvement and improvement of high temperature performance of materials.

Advantages and characteristics of corundum mullite brick

(1) High temperature resistance, high fire resistance temperature and high load softening temperature.

(2) Resistant to chemical attack and strong resistance to acidic solutions or slag.

(3) Antioxidant. It is not easy for O2, H2, CO and other gases to undergo chemical reactions.

(4) Good thermal stability, stable volume at high temperature, difficult to expand or contract.

(5) Good thermal shock resistance, resistance to rapid cold and heat, not easy to peel off.

(6) High compressive strength at room temperature, not easy to wear when handling or unloading.

Physical and Chemical Index of Corundum Mullite Bricks

Corundum mullite brick has good high temperature strength, high temperature creep resistance, thermal shock resistance and erosion resistance.

| Items | Corundum Mullite Bricks |

| Al2O3 (%) ≥ | 80 |

| Bulk Density (g/cm3) ≥ | 2.6 |

| Apparent Porosity (%) ≤ | 18 |

| Cold Crushing Strength (MPa) ≥ | 100 |

| Thermal Shock Resistance

(1000℃, Water Quenching, Cycle) ≥ |

25 |

| 0.2MPa Refractoriness Under Load (℃) ≥ | 1550 |

| Thermal Conductivity

(700℃, W/m * k) ≤ |

2.0 |

| Max Service Temperature (℃) ≥ | 1600 |

| Refractoriness (℃) ≥ | 1790 |

| Wear-resisting Degree (cm3) ≤ | 8 |

Use of Corundum Mullite Bricks

Corundum mullite bricks can be directly exposed to flames, resist spalling, and withstand high temperatures. They can be used as a thermal lining for high-temperature industrial furnaces and as a working layer for other industrial high-temperature furnaces. They are mainly used in the petrochemical industry for large and medium-sized synthetic ammonia gasification. Furnace and magnetic material gas furnace materials, high temperature industrial furnace supporting facilities materials.

Corundum mullite brick Applications:

Industrial furnace hot surface lining materials, such as annealing furnace, carbonization furnace, tempering furnace, refining heating furnace, cracking furnace, roller furnace, tunnel furnace, etc.

Industrial furnace backing insulation materials, such as glass tank kiln.

Reduction atmosphere furnace.

RS Corundum Mullite Brick Supplier

RS Kiln Refractory manufacturer provides customers with the price of Corundum mullite bricks. If you need to buy Corundum Bricks, Mullite Bricks, Corundum Mullite Bricks, etc., please contact us, and we will get back to you in the shortest time.

Rongsheng’s production factories and production technologies are leading in the industry. We have the highest configuration of refractory brick presses, and our unshaped refractory production line has been fully automated, with a daily capacity of up to 150 tons. Welcome to visit our refractory production plants. I believe that our service will make you satisfied.

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: