The raw material of magnesia brick is mainly magnesite, and its basic component is MgCO3. After high temperature calcination, it is crushed to a certain particle size to become sintered magnesia. Magnesia is widely used as a material for repairing furnaces, beating materials, and magnesia containing less impurities (ω(CaO)<2.5%, ω(SiO2)<3.5%) as a raw material for the production of magnesia bricks. RS Supplier Magnesia Brick for Sale is with high quality and the other magnesia bricks, etc.

Raw Material of Magnesia Brick for Sale

Sintered magnesia is one of the important raw materials for magnesia refractory bricks such as magnesia brick. Sintered magnesia is obtained by calcining natural magnesite or light burnt magnesia in a rotary kiln or shaft kiln at a temperature range of 1500~2300 °C. The magnesia crystals are grown and densified to be converted into inert sintered magnesia, also known as calcined magnesia. Because magnesite ore has the phenomenon of parent salt during calcination, that is, the decomposition of magnesium carbonate forms a microcrystalline polymer of cubic magnesium, the crystal structure of the parent magnesite remains, which makes it difficult to further densify the magnesium oxide. Pure magnesite is to be sintered, and the calcination temperature should be above 2000 °C. The final sintering temperature of ordinary magnesite depends on the crystallization characteristics of the raw materials and the type and amount of impurities. Generally, sintering can be achieved at 1450~1700 °C.

In order to achieve sufficient sintering of magnesium oxide, a light-burning magnesia fine grinding method is generally used to destroy the imaginary lattice of lightly burned magnesia. The high-pressure molding and the improvement of the calcination temperature and the introduction of trace additives are used to eliminate the influence of the mother salt artifact and promote the densification of the calcined product.

Characteristics of Magnesia Bricks

Magnesia Brick for Sale is alkaline refractory and have strong resistance to alkaline slag. However, it cannot resist the corrosion of acidic slag. At 1600 ° C high temperature, it can react with silica brick, clay brick, and even high alumina brick. The refractoriness of magnesia bricks https://kilnrefractory.com/magnesium-bricks/ is above 2000 °C, but its load softening point is only 1500-1550 °C. Moreover, the temperature interval at which the deformation variable starts to soften to 40% is small, only 30 to 50 °C. The thermal stability of magnesia bricks is also poor, which is an important reason for the damage of magnesia bricks.

On the heating furnace and the soaking furnace. Magnesia bricks are mainly used for laying the bottom surface of the furnace and the lower part of the soaking furnace wall. It is resistant to corrosion by iron oxide scales. In order to improve the thermal stability and high temperature strength of the magnesia brick, a fine alumina powder is added to the furnish to form a magnesia-aluminum brick combined with magnesium spinel. Large furnaces can be successfully used as high temperature roof materials and for areas where the furnace has alkaline slag corrosion.

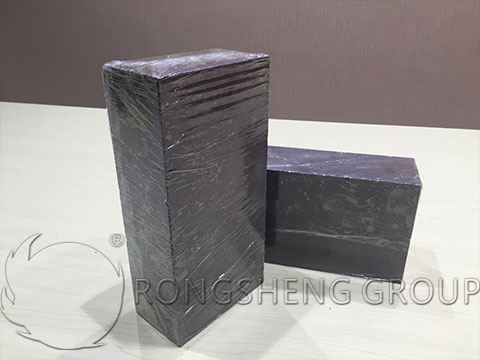

Magnesia Brick for Sale

The sintered magnesia brick is made of high-quality sintered magnesia as the main raw material, and the pulp is used as the binder. After kneading and high pressure molding, it is fired in a high temperature tunnel kiln at 1550 ° C or higher. https://kilnrefractory.com/magnesium-bricks/ Has good thermal stability, erosion resistance and flaking resistance. It is widely used in industrial furnaces such as converters and electric arc furnaces as refractory lining materials.

The fused magnesia brick has the advantages of compact brick structure, high mechanical strength and less impurity content. It is mainly used in the high temperature area of the regenerator of large glass kiln.

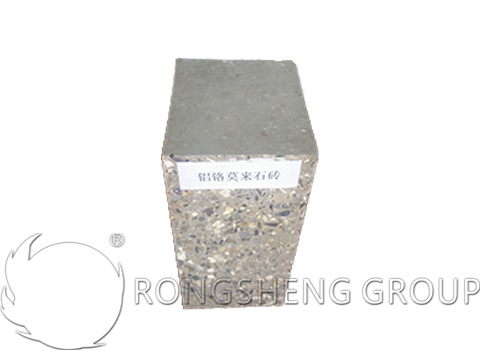

Magnesia refractories also include: magnesia-aluminum bricks, magnesia-chromium bricks, magnesia carbon bricks, magnesia-silica bricks, and the like.

Cautions of Magnesia Bricks

Magnesia bricks have poor hydration resistance, easy to hydrate with water, and cracks and reduce their strength. Therefore, pay attention to moisture, rain and snow during storage and transportation.

Magnesia Brick Manufacturer

RS is one Magnesia brick manufacturer, has been export to more than 60 countries. IF you are looking for the magnesia bricks as the refractory lining materials. Please Click: https://kilnrefractory.com/. Magnesia Brick for Sale.