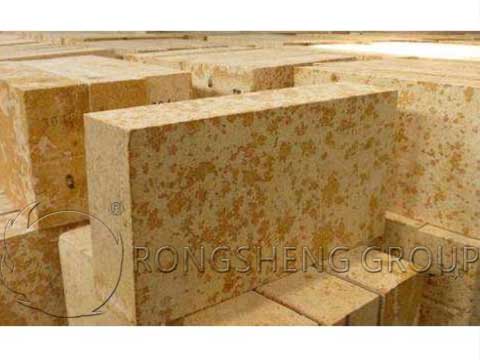

Silica bricks are acid-resistant refractory materials mainly composed of tridymite, cristobalite, and small amounts of residual quartz and glass phase, exhibiting strong resistance to acid-resistant slags. However, they are susceptible to erosion by alkaline slags and are not resistant to oxides such as Al₂O₃, K₂O, and Na₂O. Their load-bearing softening temperature is high, ranging from 1640 to 1680℃, close to the melting points of tridymite and cristobalite (1670℃ and 1713℃, respectively). Their biggest drawback is low thermal shock resistance, but their refractoriness is similar to their load-bearing softening temperature, allowing for long-term use at high temperatures without deformation, which helps ensure the structural strength of the masonry structure during use.

Silica bricks are mainly used for the partition walls of the carbonization and combustion chambers of coke ovens, as well as the roofs or vaults of soaking furnaces, hot blast stoves, acid open-hearth furnaces, and glass kilns. Currently, in ironmaking technology, new technologies such as direct reduction and molten reduction ironmaking are gradually being transformed into productive forces. In the coking industry, a type of “formed coke” produced without a coke oven has been developed, which can replace a portion of traditional coke. With the promotion of these new technologies, the demand for silica bricks will gradually decrease. However, in glass kilns both domestically and internationally, silica bricks still maintain their dominant position in the furnace arch, except for their replacement by other bricks in the regenerator lattice and some breast walls.

Like most sintered refractory bricks, silica bricks are produced using a semi-dry process and fired in tunnel kilns. Cracks during production are one of the main reasons for the high scrap rate. Analyzing the types and causes of cracks in finished silica bricks and strictly controlling the main pressing and firing processes in silica brick production can reduce crack formation and significantly improve product quality.

Types of Cracks in Silica Bricks

Cracks in silica brick products can be classified into surface cracks and internal cracks, the latter also known as lamination. Surface cracks are further divided into transverse cracks, longitudinal cracks, and network cracks. Silica bricks are produced using a semi-dry pressing method to create a dense green body. Cracks generated along the direction of pressure on the brick are transverse cracks, while cracks perpendicular to the direction of pressure are vertical cracks. Network cracks are formed when the surface of a silica brick consists of several cracks arranged in a spiderweb pattern.

Generally, for a standard silica brick, the direction of pressure on the green body is typically the thickness direction. The molding process of silica brick products is essentially a process of condensing the particles within the green body and expelling air, forming a dense green body. After machine pressing, the brick green body has advantages such as high density, high strength, low drying shrinkage and firing shrinkage, and easy control of product dimensions. However, if the machine pressing process is not properly controlled, lamination cracks perpendicular to the direction of pressure can form in the green body during the pressing process. Therefore, the lamellar cracks, or simply layered cracks, inside silica bricks are longitudinal cracks.

Large layered cracks can be detected immediately after the brick blank is formed or dried. However, tiny layered cracks within the brick blank only become noticeable after firing as they continue to propagate under thermal stress during the firing process. Silica bricks containing cracks, especially layered cracks, are prone to breakage, rendering them unusable and reducing the yield of finished silica brick products.

Formation and Main Preventive Measures of Cracks in Silica Bricks

-

Machine Press Molding

Lamination cracks in silica bricks are mainly caused by improper control of the machine press molding process, hence they are sometimes referred to as machine-pressed cracks. Both the raw material and the brick blank of silica bricks are composed of three phases: solid, water or other binders, and air. During the entire machine press molding process, also known as die pressing, the amounts of solid and liquid phases remain unchanged. However, the amount of air in the raw material is compressed and reduced due to pressure, resulting in a corresponding reduction in the volume of the compressed raw material.

During die pressing, the amount of hysteretic expansion of the blank caused by elastic aftereffects must be controlled to below 2%; otherwise, it often results in scrap during the pressing process. If a “layer density” is formed in the blank along the direction of pressure, with a density difference greater than 2%, laminar cracks are easily generated inside the brick blank. This leads to uneven thermal expansion during firing, generating significant thermal stress and forming longitudinal cracks parallel to the density layers, ultimately resulting in scrap.

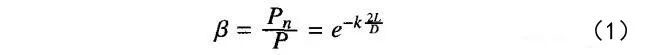

In compression molding, pressure is used to overcome the internal friction between particles, the external friction between particles and the mold wall, and the deformation of the pressed blank. As the distance from the pressure head increases, the internal pressure of the blank decreases. Based on the expression for the uniformity of the pressed blank:

In equation (1), β represents the uniformity of the pressed blank, P represents the surface pressure of the blank, Pn represents the internal pressure of the blank, L represents the length of the blank, D represents the bearing diameter of the blank, and k is a coefficient related to the physical properties of the blank.

Therefore, when pressing silica bricks, it is advisable to use short molds with a small aspect ratio and avoid using high molds with a large aspect ratio to improve the uniformity of pressure distribution within the blank. Simultaneously, introducing certain plasticizers and surfactants into the blank can reduce internal friction and pressure transmission loss. Improving the surface finish of the mold or applying oil to the mold can reduce external friction of the blank. Double-sided pressing can reduce the L/D ratio of the blank. Multiple pressing methods, starting lightly and gradually increasing pressure, can prevent excessive pressure accumulation within the brick blank and eliminate elastic aftereffects, thereby improving the uniformity of internal pressure and density. This avoids areas closer to the pressure surface having a higher density and areas farther from the pressure surface having a lower density, reducing the formation of layer density defects that can lead to cracks.

Furthermore, silica brick blanks are prepared by mixing aggregates, clinker, ball mill powder, mineralizers, sulfite pulp waste liquor, and plasticizers. Improving the kneading process of the blanks also helps to increase the density of the brick blanks. In terms of material mixing technology, the movement of materials between the same phase is called mixing, the movement between different phases is called stirring, and the operation of mixing high-viscosity liquids and solids is called kneading (kneading and mixing). Through proper kneading, fine powder can coat large particles, effectively remove gas, improve the density of the blanks, and thus reduce the porosity of the brick blanks.

-

Firing Process

The sintering of silica bricks is essentially a polycrystalline transformation of SiO2. Under the action of a mineralizer, the silica raw material is slowly fired, essentially transforming into tridymite and cristobalite, with only a small amount of residual quartz. When silica bricks are heated to 1450℃ during use, they exhibit a 1.5%–2.2% total volume expansion. This residual expansion ensures tight joint sealing, contributing to the good compactness and structural strength of the silica brick masonry. Furthermore, this polycrystalline transformation of SiO2 dictates that the focus of refractory material monitoring during the early stages of kiln firing should be on silica bricks, with a slow and uniform heating rate. Within the temperature range of 150–300℃, the crystal transformation of β- and α-cristobalite in silica bricks is accompanied by a significant volume effect; therefore, special attention should be paid to slow heating within this temperature range during kiln firing.

The rate and extent of the quartz to tridymite transformation are related not only to the temperature and the presence of the mineralizer but also to factors such as the duration of temperature exposure, the particle size of the raw material, and the crystal size of the transformed phase. Higher temperatures, longer exposure times, smaller particle sizes, smaller crystals, and stronger mineralizing agents result in faster transformations, and vice versa. The main crystalline phases of silica bricks are tridymite and cristobalite. Tridymite has a melting point of 1670℃ and exhibits high volume stability. If the tridymite in the silica brick is distributed in a spearhead-shaped twinning pattern in a network, it can give the silica brick a higher load-bearing softening point and mechanical strength. When there is a large amount of residual quartz in the silica brick, it will continue to undergo crystal transformation during use, resulting in significant volume expansion and potentially causing the brick structure to loosen and crack.

The physical and chemical changes that occur during the firing process of silica bricks can be summarized as follows:

- ① Residual moisture in the brick blank is removed at temperatures below 150℃.

- ② Ca(OH)₂ begins to decompose at 450–550℃, and decomposition is complete at 550℃. At this point, the bond between silica brick particles is broken due to the action of CaO, etc., resulting in decreased strength and brittleness of the brick body.

- ③ At 550–650℃, β-quartz bricks transform into monoquartz, causing volume expansion.

- ④ At 600–700℃, a solid-phase reaction occurs between CaO and SiO₂, increasing the strength of the brick body.

- ⑤ At 800–1100℃, a liquid-phase reaction occurs in the brick blank, rapidly increasing its strength. From 1100℃ onwards, the transformation rate of quartz increases significantly, resulting in a low-density quartz variant with substantial volume expansion.

- ⑥ At 1300–1350℃, the increased amount of tridymite and cristobalite decreases the true specific gravity of the brick body, and the increased volume expansion may lead to cracking.

- ⑦ At 1350–1470℃, the degree of quartz transformation and the resulting expansion are significant. Only monoquartz, metastable cristobalite, mineralizers, and impurities interact to form a liquid phase, which intrudes into the cracks that appear in the quartz particles during the formation of metastable cristobalite. This promotes the continuous dissolution of monoquartz and metastable cristobalite in the formed liquid phase, making it a supersaturated melt of silicon and oxygen. Then, stable trichomes continuously crystallize from the melt. At this point, the higher the viscosity of the liquid phase, the faster the transformation rate of the silica brick, and the greater the likelihood of cracks forming in the brick blank.

Therefore, to prevent the formation of cracks due to crystal transformation and large volume changes during the firing process of silica bricks, the following process measures must be taken:

- (1) Control the heating rate within different firing temperature ranges. The heating rate should be slowed down below 600℃, and accelerated between 600 and 1000℃. The heating rate should be slow between 1100 and 1300℃, and the heating rate should be the slowest during the firing process from 1300℃ to the firing temperature (1430℃ to 1450℃). The silica bricks should be cooled below 600℃ after firing, especially at 300℃. This effectively buffers the volume changes caused by crystal transformation, resulting in higher contents of tridymite and cristobalite, and preventing crack formation.

- (2) A reducing atmosphere should be used during the high-temperature firing stage, which is beneficial for the mineralization of low-valent iron oxide and promotes the formation of large amounts of tridymite. Otherwise, under an oxidizing atmosphere, especially when the mineralizer is insufficient, α-quartz mostly transforms into α-cristobalite; this transformation is called “dry conversion.” During dry conversion, the uneven volume expansion of the brick body, coupled with the lack of liquid-phase buffer stress, leads to a loose product structure and cracking. Simultaneously, appropriate heat preservation should be carried out at different temperature stages during the firing of silica bricks to ensure a reasonable phase composition that meets usage requirements.

- (3) Improve the semi-finished product loading process to reduce the probability of cracking. Transverse cracks in silica bricks, i.e., cracks parallel to the pressure direction of the product, are usually caused by uneven heating of different parts during firing. They often appear on the outer surface of the brick stack, especially on the surface of the top layer. Surface network cracks in silica bricks, besides being caused by uneven kneading or changes in raw materials leading to microscopic inhomogeneity in the green body itself, are usually caused by excessively high and fluctuating heating temperatures. When loading the kiln car, special-shaped silica bricks should be placed inside, while standard bricks should be placed outside. The protruding parts or crack-prone areas of the special-shaped bricks should face inwards. The top of the kiln car should be covered with thin brick sheets to prevent direct impact from the flames; otherwise, cracking will increase.

Rongsheng Silica Brick Price

Cracks are one of the main factors affecting the yield and performance of silica bricks. Mastering the pressing and firing processes is crucial to preventing crack formation in silica bricks. The theoretical and actual conversion of silica raw materials differ, requiring real-time adjustments to the firing regime based on changes in raw materials and brick type. The preparation and quality of silica brick blanks are important, even critical, factors. Only by strictly controlling each process step can high-performance silica brick products be produced efficiently and with low consumption. Rongsheng Silica Brick Manufacturer supplies high-quality silica brick products. Contact Rongsheng for free samples and quotations for Silica Brick Price.