The core issue surrounding the cement kiln is the burner, including proper burner primary air volume and flame momentum. In addition, the friendliness of the burner to refractory bricks, the relationship between flame temperature and NOx generation, and the disposal of combustibles in the kiln head in the future are all issues that need to be considered.

(1) Primary Air Volume and Adjustability of the Burner

The shape of the flame needs to be adjusted by the primary air, and the two most important parameters are the primary wind momentum and the swirl number. In theory, the greater the momentum of the primary air, the higher the high-temperature secondary air that can be engulfed. The relationship between the two is linear, but it does not mean that the entrainment speed of the secondary air is the same. The primary wind momentum please the primary wind volume and wind speed. If the primary airspeed is increased as much as possible, can’t the primary air volume be reduced, which will help reduce heat consumption and NOx emissions?

It’s not that simple in actual operation. Under the same primary wind momentum, the higher the wind speed, the lower the wind volume, the better.

In Holcim’s technical documents, the recommended primary air ratio is 10%-12%. Relative to the amount of air required for theoretical combustion of the first coal, the excess air coefficient of the smoke chamber is not considered. At the same time, coal supply air is not included.

It can be seen that this primary wind ratio is not so low. Furthermore, the data pointed out that according to Holcim’s experience in using low primary air volume burners, the technically lowest limit of primary air ratio is 6%-8%, below this ratio, stable combustion conditions cannot be guaranteed. Even if the primary air ratio is 6%-8%, once there is any fluctuation in the combustion process, it will cause the combustion to shift to the end of the kiln, which will increase the temperature of the smoke chamber and reduce the quality of clinker.

The experience gained by Holcim may be mainly based on the adjustability of the burner. For example, if a burner with the same momentum is designed, a burner with a small primary air volume must have a high wind speed. When the combustion process fluctuates, such as the flammability of the raw meal becomes worse and the volatile content of the pulverized coal becomes lower, the momentum of the burner needs to be increased. At this time, designing a burner with a small primary air volume may not be able to further increase its ejection speed, thus limiting the increase in primary air momentum.

(2) The Influence of Primary Wind Speed Change on Flame Length

There is basically no objection to the effect of the swirling wind change on the flame length, that is, as the swirling wind increases, the flame becomes shorter and thicker. However, different companies have completely different conclusions about the influence of changes in the axial flow on the flame length. As mentioned in the adjustment of the Lafarge burner, the speed of the axial flow increases and the flame will shorten. However, according to the actual experience of some companies, the increase in the speed of the axial flow, the longer the kiln shell, and the increase in the temperature of the smoke chamber, which means that the flame is also longer. Why is this so?

The reason is that the increase in primary wind speed can be understood as axial flow wind. On the one hand, the range of coal powder is increased, which may extend the flame. On the other hand, the mixing of coke particles and secondary air is strengthened, which is beneficial to accelerate the combustion of carbon particles and may shorten the flame. Therefore, when the primary wind speed changes, how the flame length changes depend on the combined result of the two factors mentioned above.

In other words, after the axial flow increases, does the flame lengthen? This is affected by many factors such as the volatile content of pulverized coal, moisture, particle size, secondary air temperature, and the operation of existing burners. Of course, specific issues require specific analysis.

(3) What is the Appropriate Amount of Wind Momentum?

The primary wind momentum summarized by different burner manufacturers or cement companies is not the same. For example, the primary wind momentum recommended by Holcim is 7-10 N/MW (including coal supply air). So how much wind momentum is appropriate?

If the primary air momentum is too small, the entrained secondary air volume is limited, and the ideal flame shape cannot be formed. If the wind momentum is too large, it will increase power consumption or heat consumption on the one hand, but it is meaningless on the other hand. The entrained secondary air volume is related to the primary air momentum, and the secondary air volume is fixed.

So how to evaluate whether a wind momentum is appropriate? The answer is whether the burner has an external circulation.

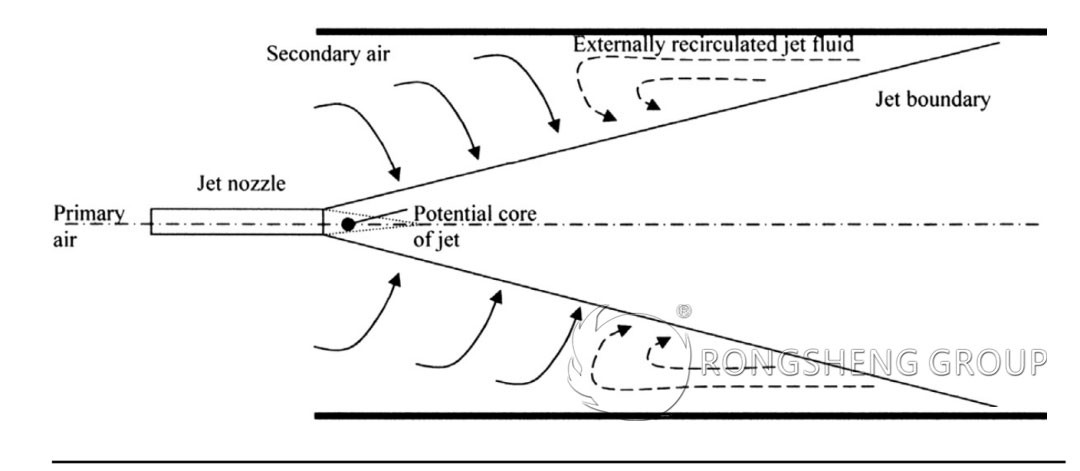

As shown below. During the operation of the combustor, there are two areas of internal circulation and external circulation. The inner circulation has a positive meaning for stabilizing the flame; the outer circulation can be used as a basis for characterizing whether the burner momentum is appropriate!

If there is no external circulation during the production process, it indicates that the momentum of the burner is insufficient at this time. In other words, not all the secondary air is entrained into the flame. At this time, even if the oxygen concentration in the smoke chamber is high (such as 2%-4%), more carbon monoxide will be produced. If the momentum of the burner is appropriate, an external circulation will be formed, indicating that all the secondary air has been entrained into the flame. At this time, only when the excess air is small, if the oxygen concentration in the smoke chamber is less than 0.5%, more carbon monoxide will be produced.

Finally, again, if it’s mixed, it’s burnt well.

Recommended Refractory Materials for Cement Kiln Burners

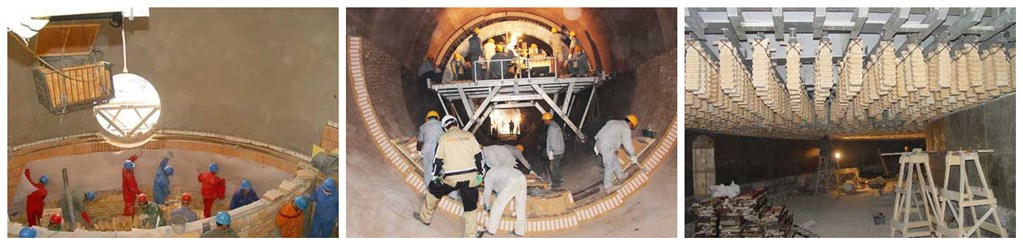

Having said so much, how can we ensure the normal operation of the burners of cement kilns? Of course, high-quality refractory lining materials cannot be ignored. Rongsheng kiln refractory material manufacturer provides high-quality refractory lining materials for various parts of the cement kiln. Rongsheng refractory manufacturer recommends that in coal injection pipes, corundum-mullite castables, steel fiber reinforced castables, low-cement and high-alumina castables are often used. The material of the tertiary air duct mainly considers abrasion resistance, alkali resistance, and peeling resistance. High-strength alkali-resistant bricks, high-strength alkali-resistant castables, and anti-skinning castables can be used. Purchase high-quality refractory materials for cement kilns, such as magnesia-chrome bricks, spinel bricks, anti-stripping high alumina bricks, silica bricks, high alumina bricks, and various high-strength wear-resistant castables. Please leave your specific requirements on our website page. We will provide you with refractory material products that best suit your production needs according to your specific needs.

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: