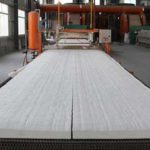

Ceramic Fiber Module is a kind of thermal insulation refractory materials for kiln lining construction and improving kiln integrality. Ceramic Fiber Module can be fixed on the refractory anchor nails of kiln shell steel plate in the industrial kiln with the features of white color and regular sizes that . Ceramic Fiber Modules have good thermal insulation effect that can improve the integrality of kiln insulation, which can be used as refractory insulation materials in ceramic industry and steel industry. Welcome to Contact Us for Detailed Information.

Ceramic Fiber Module Properties

- Great elasticity

- Easy construction

- Light weight

- Good chemical stability

- Excellent thermal insulation

- Excellent thermal stability

- Low heat storage capacity

- Good thermal shock resistance

Ceramic Fiber Module Application

Ceramic Fiber Module can be used as thermal insulation refractory for kiln lining in the petrochemical industry, metallurgical industry, ceramic and glass industries, heat processing industry and other industries.

Ceramic Fiber Module For Steel Industry

|

Ceramic Fiber Module For Ceramic Industry

|

Ceramic Fiber Module For Other Industries

|

Ceramic Fiber Module Classification

Ceramic Fiber Module can be classified into the following types according to the different molding methods:

- Module, including collapse block, block slice and vacuum forming block.

- Due to the different of polycrystalline mullite fibre production methods and the crystal orientation structure, the fiber length is shorter and softness, which cannot be made into big modules that prevent polycrystalline fiber from large-scale application. Now polycrystalline fiber is more used as module block in the castable or kiln refractory brick wall, roof surface, which can effetely reduce the temperature of furnace wall and heat loss at the same time.

Ceramic Fiber Module can be classified into the following types according to the temperature grade:

- 1050 Common Ceramic Fiber Module

- 1260 Standard Ceramic Fiber Module

- 1260 High Purity Ceramic Fiber Module

- 1400 High Alumina Ceramic Fiber Module

- 1400 Low Zircon Ceramic Fiber Module

- 1400 Zircon Ceramic Fiber Module

Ceramic Fiber Module Specification

| Classification Temperature | 1260 | 1400 | |||

| Products Code | RSNC-289 | RSNC-389 | RSNC-489 | RSNC-589 | |

| Heating Permanent Linear Change (%) | 1000℃*24h≤-3 | 1100℃*24h≤-3 | 1200℃*24h≤-3 | 1350℃*24h≤-3 | |

| Theoretical Thermal Conductivity

(W/m*k) |

Average 200℃ | 0.045-0.060 | |||

| Average 400℃ | 0.095-0.120 | ||||

| Average 600℃ | 0.160-0.195 | ||||

| Theoretical Bulk Density (kg/m3) | 200±10, 220±10 | ||||

| Products Specification | 300*300*200/250 | ||||

| Al2O3 (%) | ≥45 | ≥45 | 52~55 | – | |

| ZrO2 (%) | – | – | – | 15~17 | |

| Al2O3 + SiO2 (%) | ≥97 | ≥99 | ≥99 | – | |

| Al2O3+SiO2+ZrO2 (%) | – | – | – | ≥99 | |

| Fe2O3 (%) | ≤1.0 | ≤0.2 | ≤0.2 | ≤0.2 | |

| K2O+Na2O (%) | ≤0.5 | ≤0.2 | ≤0.2 | ≤0.2 | |

Ceramic Fiber Module Manufacturer

Rongsheng is a professional ceramic fiber module manufacturer in China. We have advanced manufacturing technology and production equipments for supporting the products quality and cost control. Buy Ceramic Fiber Modules, ceramic fiber module anchor from RS Refractory Materials Supplier! There are high quality and cheap ceramic fiber module insulation refractory materials for sale! Contact us for the ceramic fiber module price.

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: