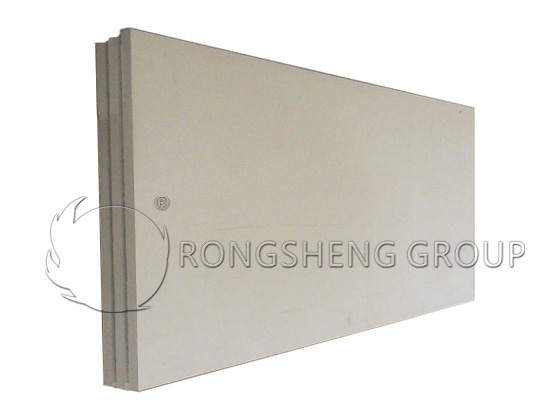

Fiber-reinforced calcium silicate board is a new type of lightweight board made of calcium materials, silica materials, and other cementing materials and reinforcing fibers (mostly cellulose fibers, alkali-resistant glass fibers, etc. instead of asbestos fibers) as main raw materials, which are formed and cured by steam or high-pressure steam. RS supplier of calcium silicate board 50 mm thick, free quote and direct delivery from the manufacturer.

Product types and uses of fiber-reinforced calcium silicate board

Types of fiber-reinforced calcium silicate board

- Asbestos fiber-reinforced calcium silicate board is divided into ordinary board (code A) and high-grade board (GA).

- Non-asbestos fiber-reinforced calcium silicate board is divided into ordinary board (code N) and high-grade board (GN).

Apparent density

Divided into three categories: D0.8, D1.0, D1.3. Note: 0.8, 1.0, 1.3, etc. are all subscripts.

Uses of fiber-reinforced calcium silicate board

- Fiber-reinforced calcium silicate board for construction: the board thickness is generally 5~12mm.

- Fiber-reinforced calcium silicate board for ships: the board thickness is generally 15~35mm.

Product features of fiber-reinforced calcium silicate board

Advantages of fiber-reinforced calcium silicate board. Fiber-reinforced calcium silicate board is a board made of calcium and silicon materials in the base material, which are autoclaved and cured in a container with a certain pressure and temperature, and undergoes a hydrothermal synthesis reaction to form tobermorite with a stable crystal structure. The material is stable and the shrinkage rate caused by temperature and humidity is extremely small. The difference between fiber-reinforced calcium silicate board and ordinary calcium silicate board is that the amount of reinforcing fiber in the board is more than 5%. Therefore, it has the advantages of low density, moisture resistance, moth resistance, mildew resistance and good processability (can be nailed, sawed, planed, drilled, glued [1], etc.), which are also possessed by ordinary calcium silicate board. Fiber-reinforced calcium silicate board also has excellent properties such as high strength, small shrinkage and swelling, and small flexural deformation. Fiber-reinforced calcium silicate board has excellent fire resistance. It will not explode or burn in an open flame, nor will it produce smoke and toxic gases. The partition wall with a total thickness of 91mm is composed of 8mm thick fiber-reinforced calcium silicate boards on both sides, light steel keels and 60mm thick rock wool. According to the national standard GB9978-1988, the fire resistance limit can reach more than 90min. The lightweight composite board made of thin fiber-reinforced calcium silicate board as the panel and filled with light core materials such as foam polystyrene light concrete or foam expanded perlite light concrete in the middle has low self-weight, good sound insulation and heat insulation effect, fast construction speed, and lower price than the wallboard compounded on site with light steel keels.

Disadvantages of fiber-reinforced calcium silicate board. The main disadvantage of fiber-reinforced calcium silicate board as a microporous calcium silicate insulation material is strong water absorption. It is difficult to use traditional cement mortar to plaster during construction, the surface is easy to crack, and the plastering material is not easy to bond with the substrate. Special plastering materials must be used.

Application fields of fiber-reinforced calcium silicate board

Fiber-reinforced calcium silicate board for construction is lightweight, high-strength, non-combustible, heat-insulating, has small dry-wet deformation and good processing performance, so it can be used as wall panels and lightweight partition boards for composite walls under various conditions. It is particularly suitable for the inner and outer walls of composite walls, and is used as partition boards for public and civil buildings. It can also be used as suspended ceilings and ceilings. It is a very promising thin board for construction. After surface waterproofing treatment, it can also be used as the exterior wall roofing panel of the building. Fiber-reinforced calcium silicate board has good moisture-proof performance, so it is also suitable for humid environments, such as bathrooms, kitchens, toilets and basements. At the same time, fiber-reinforced calcium silicate board is also suitable for movable floors, used in computer rooms, warehouses and warehouses with fire and moisture requirements. Fiber-reinforced calcium silicate board composite wall panels can be used as household walls, internal partition walls and external walls of buildings. High-end buildings should use high-grade boards (GN) among non-asbestos fiber-reinforced calcium silicate boards (and specify that they absolutely do not contain asbestos). For mid-range buildings, it is advisable to use high-grade boards among non-asbestos fiber reinforced calcium silicate boards, or ordinary boards (N) reinforced with non-asbestos fibers or high-grade boards (GA) reinforced with asbestos fibers. For general buildings, ordinary boards (A) reinforced with asbestos fibers can be used. For food processing, pharmaceutical and other buildings, internal partition walls should not use boards containing asbestos.

The production process of fiber-reinforced calcium silicate board

The production of fiber-reinforced calcium silicate board in China mainly adopts two processes: copying molding and slurry flow method.

- Copying molding. The copying method is suitable for making large-size thin plates with a thickness of 6~12mm and an apparent density of 600~1200kg/m³, which can be used as interior and exterior wall panels, ceilings, etc. of buildings.

- Compression molding. The compression molding method is suitable for making plates with a thickness of 19~32mm and an apparent density of 750~900kg/m³. The original plate of the compression molding method can be painted and colored or ground and sanded as a ceiling brick slab to become a core plate. The core plate can be packaged and shipped after inspection, or further processed to make a decorative panel or composite wall material.

Notes

Fiber-reinforced calcium silicate board can be packed in hard packaging boxes. If other packaging methods are used, the board should not be bent and the board edge should not be damaged by collision. The packaging height should not exceed 1.2m. When transporting and loading and unloading boards, the board length should be the stress edge. It is not allowed to collide with each other or throw from any height. The bottom of the transport vehicle must be flat and the product must be fixed. During transportation, vibration should be reduced to prevent collision and rain.

Boards should be stacked according to different specifications and categories, and the stacking height should not exceed 3.6m. The stacking site must be flat and solid, and outdoor stacking should be covered. If square wood is used for padding, the product should not be deformed.

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: