How many furnaces can generally be used for ladle castables? What is the service life of the ladle castable? According to the sales experience of refractory castable manufacturers for many years, generally, the service life of ladle castable lining can reach 80~120 furnace times. The raw material of ladle castable is similar to Al-Mg spinel. In fact, if the ladle is repaired regularly, its practical life can reach 130~160 times.

Application of Ladle Castable

A ladle is a container that plays a key role in the entire ironmaking process. Extend the service life of the ladle and reduce the consumption of refractory lining materials. It can save a lot of production costs for steel mills.

Ladle castables are mainly magnesia or high alumina spinel. The refractory aggregate is pure magnesia or high alumina clinker, and the refractory powder is magnesium aluminum spinel powder. The binder is a composite binder, and additives are added at the same time. Ladle castables have good slag resistance, spalling resistance, and thermal shock resistance. Compared with magnesium-aluminum spinel refractory castables, the performance is slightly lower, the cost is significantly lower, it is suitable for national conditions, and it is easy to promote. Compared with ordinary aluminum-magnesium refractory castables, due to the addition of spinel instead of gradually forming spinel during use, its performance is significantly improved, the cost can be accepted by users, and its service life is extended, so it has broad prospects. According to different application standards, different types and specifications of ladle castables are configured. It can be roughly divided into general aluminum-magnesium castables, slag line and cladding composite aluminum-magnesium castables, high-grade aluminum-magnesium castables, and aluminum-magnesium spinel castables.

Characteristics of Ladle Castables

- Strong corrosion resistance to molten iron and slag.

- Good thermal shock resistance, a small change in re-burning volume.

- Strong antioxidant capacity.

- Convenient construction, fast baking without bursting, easy maintenance, and disassembly.

- No harmful gas is produced during use, no sticky residue, and long service life.

- Resistant to thermal shock, it can be filled with molten steel repeatedly without cracking or peeling off.

- Resistant to slag erosion, able to withstand the erosion of slag and slag alkalinity changes on the inner lining.

Ladle castables are one of the containers that transport molten steel from the ironmaking blast furnace to the pouring section. As one of the main causes of ladle castable damage, the penetration of slag into the castable will lead to deterioration of the properties of the raw material. Therefore, the quality of slag resistance of ladle castables directly endangers its service life. It has been found in continuous practice that adding spinel to corundum castables can reasonably improve the slag resistance of the raw material.

With the development of production technology in ironworks, the development trend of rolling and refining outside the furnace relatively increases the waiting time of molten steel in the ladle. Thereby accelerating the damage of molten steel to the inner lining of the ladle, resulting in the low service life of the ladle and shortened service life of the ladle. Therefore, the application of high-quality ladle refractory castables is necessary.

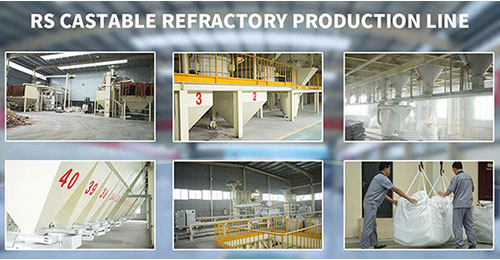

Rongsheng refractory castable manufacturer, according to the needs of customers, taking into account the needs of the development of the ironmaking industry, refractory castables for ladles are also constantly improving and developing. In order to obtain castables with excellent functions, on the basis of learning the experience of ladle castables, strict selection and control of particle size grades are carried out. It is 1~10 mm, accounting for 65%~70%. Select the fine powder whose particle size is less than 0.088 mm, accounting for more than 95%, and its dosage accounts for 30%~35%.

With the accelerated pace of technological innovation of ladle castables, similarly, labor costs, refractory consumption, and industrial waste are reduced, greatly increasing the service life of ladle refractories. The service life of the ladle castable is extended, and the production cost is saved. All in all, the service life of ladle castable as ladle lining will increase with the development of ladle refractory castable lining. Contact us for free samples and the latest price information on long-life ladle castables.

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: