Monolithic refractories, a kind of unshaped refractory, are made of refractory aggregate and powder with a certain grain size distribution, binding agent, and admixture. The monolithic refractory materials can be directly used for the lining of thermal equipment by baking without the firing process. Monolithic refractory own features of simple process, energy-saving, low cost, and easy mechanized construction. Compared by the using effect, monolithic refractory is better than firebrick for some heating equipment applications.

Various Monolithic Refractories For Sale In Rongsheng Refractory Manufacturer

Description for Monolithic Refractories

Monolithic refractories are used directly by mixing of refractory aggregate and powder with a certain grain size distribution, binding agent, and admixture together, without firing process. Monolithic refractory has no fixed shapes that can be made to be pulpiness, paste, and loose material, mostly be used to build monolithic construction.

Aggregate and powder of monolithic refractories can be any texture for refractory materials. Monolithic refractory can be classified to be fireclay refractory, high alumina refractory, silica refractory, magnesia refractory, dolomite refractory, and chrome refractory according to the texture of raw material. There are sorts of binding agents such as various cement, mineral salt, and organic matter. Monolithic refractories also can be classified into castable refractory, ramming mass, plastic refractory, slinging refractory, refractory mortar, fireproof paint and etc. according to processing property.

Types of Monolithic Refractories

Monolithic refractories can be classified into castable refractory, plastic refractory, ramming mass, gunning mix, slinging refractory, fireproof paint and etc. according to the construction method and material property.

Castable Refractory

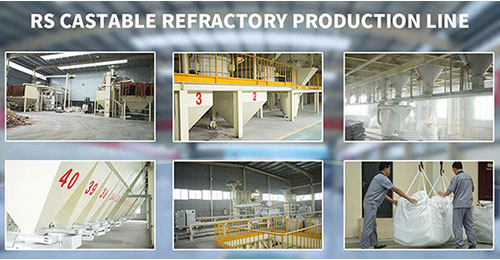

Castable refractory is a kind of fluid unshaped refractory that doesn’t need firing after adding water. The castable refractory adopts aluminum silicate clinker, corundum material or alkaline refractory clinker as the aggregate and uses calcium aluminate cement, ethyl silicate, aluminum polychlorid, sodium silicate, clay or phosphate as the binding agent. Admixture application is subjected by service condition, it can improve the workability, physical and chemical property of the castable refractory.

Adopt one construction method of vibration, pump casting, or spray to build monolithic furnace lining with metal or ceramic anchoring parts. By adding stainless steel fiber to improve mechanical vibration and thermal shock resistance. Refractory castable can be used for linings of thermal treatment furnace, molten tin bath, salt bath furnace, tapping tank or launder, reforming furnace and etc. And also commonly used in a high-temperature industrial kiln in a blast furnace, hot blast stove, heating furnace, boiler, pellet furnace, and other industries.

Plastic Refractory

Plastic refractory is a kind of amorphous refractory material in the form of hard-paste, which is composed of granular and powdery materials, combined with plasticizer and other binders and plasticizers, then adding a small amount of water, and finally fully mixed. It maintains high plasticity for a long time.

Adopt a construction method of ramming or vibration to repair monolithic furnace lining equipped with metal or ceramic anchoring parts. The plastic refractory always be used for linings of soaking pit, heating furnace and etc. and also can be used to bind up the water-cooled valve of the heating furnace.

Ramming Mass

Ramming mass is a kind of unshaped refractory material with low plasticity or without plasticity. There are various materials such as silica, fireclay, high alumina, corundum, zirconite, carborundum, carbonaceous, magnesian and etc. According to the material and service conditions, adopts inorganic bond or organic bond that similar to castable refractory such as hydrosoluble dextrin, carboxymethylcellulose, xylogen, sulfonate, poval and water-resistant and with plasticity paraffin, pitch, tar, phenolic resin, Atactic Polypropylene and etc.

Ramming mass adopts forced ramming construction with features of lower apparent porosity and higher bulk density. Among the unshaped refractory materials, ramming mass is specially suitable used for smelting furnace lining and all kinds of container lining for molten metal, such as electric furnace and bottom of the open-hearth furnace, all kinds of induction furnace lining, an iron runner for blast furnace, molten steel ladle and etc.

Gunning Mix

Gunning mix is a kind of refractory mix material and is used to spray repair by gunning equipment. According to gunning methods, gunning mix refractory can be classified into wet gunning (or gunning mortar method), half dry gunning, and fire flame gunning.

There are many types for gunning mix such as alumina-silica, alumina-silica zirconium, magnesia, magnesia-calcium, magnesium and chromium and etc. The normally binding agents have sodium silicate, phosphate, polyphosphates, pitch, resin and etc. Add fireclay, lime and etc. to improve adhesive rate. Add agglutinants such as serpentine, olivine, lime, fireclay, and iron oxide to make sure that the gunning mix can reach up to a good sintering state.

Fireproof Paint

Fireproof paint is an unshaped refractory material that coating on the firebrick lining. According to the different service conditions and construction methods, fireproof paint can be made into paste and mortar form. According to its property to choose and use binding agent material. Use basic coatings such as polyphosphates, magnesium sulfate, and magnesium sulfate for tundish of continuous casting. Use fireclay, aluminum dihydrogen phosphate, ACPB, and sodium silicate to make high alumina coating. Add additive plasticizer to improve workability. Fireproof paint is mainly used for protective coating of heating equipment lining or repairing local damage of bricking.

Slinging refractory

Slinging refractory is a kind of half-dry and unshaped refractory material, which is mainly used to build the lining of monolithic molten steel ladle through a slinging machine. There are various types such as silica, pyrophyllite, fireclay, high alumina and zirconite and etc. Of which high silica and high alumina slinging refractory are most commonly used.

The Construction Method of Monolithic Refractories

There are several methods for the construction of monolithic refractory materials, such as ramming process, vibration molding, gunning, and slinger process, etc.. Use this king of refractory material to replace or cold and hot repair through painting or slinging when the local of firebrick masonry or monolithic construction is damage, It is easy to construction and also save money. Monolithic refractory can be used for the lining of all kinds of the position of furnace or kiln and protective layer and joint sealing material for masonry based on its materials’ properties.

Cheap Monolithic Refractories For Sale

RS Company is a professional monolithic refractories manufacturer and provides customers with all kinds of cheap unshaped refractories. All kinds of Monolithic Refractory materials for sale, such as castable refractory, refractory cement, refractory mortar, plastic refractory, refractory coating, refractory concrete, and so on. Any need? Contact Us To Get The Lower Monolithic Refractories Price Please!

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: