In industrial applications where extreme temperatures are the norm, the materials used in construction and maintenance must be able to withstand intense heat without compromising structural integrity. Among these materials, carbon bricks have emerged as a critical component in high-temperature environments, such as blast furnaces, aluminum reduction cells, and other metallurgical operations. One of the key properties that make carbon bricks so valuable in these settings is their thermal conductivity—understanding why thermal conductivity matters in extreme conditions is essential for making informed decisions about material selection and application.

What Are Carbon Bricks?

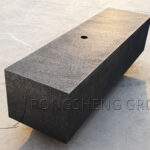

Carbon bricks are a type of refractory material known for their high thermal resistance, low thermal expansion, and exceptional durability. They are made primarily from carbon-rich materials, such as graphite or anthracite, and are often used in environments where they will be exposed to high temperatures, corrosive chemicals, and mechanical stress.

The manufacturing process of carbon bricks involves mixing carbon-based materials with binders, forming them into the desired shape, and then subjecting them to high temperatures in a kiln to remove any volatile components. The result is a dense, durable brick that can withstand the harshest industrial conditions.

The Importance of Thermal Conductivity

Thermal conductivity is a measure of a material’s ability to conduct heat. In the context of carbon bricks, thermal conductivity plays a crucial role in determining how effectively the brick can transfer heat from one side to the other. This property is especially important in high-temperature environments, where efficient heat transfer can significantly impact the performance and longevity of the refractory lining.

Why does thermal conductivity matter? In extreme conditions, where temperatures can reach several thousand degrees Celsius, the ability of a material to conduct heat efficiently can influence several factors, including:

- Temperature Management: In industrial processes, maintaining a stable temperature is essential for consistent operation. Carbon bricks with high thermal conductivity help distribute heat evenly across the surface, preventing hotspots that could lead to premature wear or failure of the refractory lining.

- Energy Efficiency: Efficient thermal conductivity means that less energy is required to achieve the desired temperature distribution. This can lead to significant energy savings, particularly in large-scale operations where energy costs are a major concern.

- Structural Integrity: High temperatures can cause materials to expand and contract, potentially leading to cracking or other forms of damage. Carbon bricks with appropriate thermal conductivity can help mitigate these effects by ensuring that heat is evenly distributed, reducing the risk of thermal stress.

- Operational Safety: In processes involving molten metals or other hazardous materials, the integrity of the refractory lining is crucial for preventing accidents. Carbon bricks with high thermal conductivity help maintain a stable temperature, reducing the likelihood of catastrophic failure.

Applications of Carbon Bricks in High-Temperature Environments

Due to their excellent thermal conductivity, carbon bricks are widely used in industries that operate at extreme temperatures. Some of the most common applications include:

- Blast Furnaces: In the steel industry, blast furnaces are used to reduce iron ore into molten iron. The interior of a blast furnace is lined with refractory materials, including carbon bricks, to protect the structure from the intense heat generated during the smelting process. The thermal conductivity of carbon bricks ensures that the heat is evenly distributed, preventing localized overheating and extending the life of the furnace lining.

- Aluminum Reduction Cells: In the production of aluminum, carbon bricks are used to line the reduction cells where alumina is converted into molten aluminum through electrolysis. The high thermal conductivity of carbon bricks helps maintain the required temperature for efficient electrolysis while also protecting the cell structure from thermal stress.

- Coke Ovens: Coke ovens are used in the production of coke, a fuel derived from coal that is essential in the steelmaking process. The ovens operate at extremely high temperatures, and carbon bricks are used to line the oven walls to ensure even heat distribution and prevent damage to the structure.

- Chemical Industry: In processes that involve the handling of corrosive chemicals at high temperatures, carbon bricks are used to line reactors, kilns, and other equipment. Their thermal conductivity helps maintain the necessary temperature for chemical reactions while also providing resistance to chemical attack.

The Importance of Thermal Conductivity in Carbon Bricks

The importance of thermal conductivity in carbon bricks cannot be overstated, particularly in extreme conditions where temperature control, energy efficiency, and structural integrity are paramount. By ensuring efficient heat transfer, carbon bricks contribute to the overall performance and longevity of industrial operations, making them an indispensable material in high-temperature environments.

As industries continue to push the boundaries of temperature and performance, the demand for high-quality carbon bricks with superior thermal conductivity will only grow. Understanding the role that thermal conductivity plays in these settings is crucial for engineers, manufacturers, and operators alike, as it allows for better material selection and ultimately, more efficient and safer industrial processes.

In summary, carbon bricks are more than just a protective lining—they are a critical component that directly influences the success of high-temperature industrial applications. Their thermal conductivity is a key factor in their effectiveness, making them an essential material in any operation where extreme heat is a constant challenge.

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: