In the refractory materials field, the demand for custom-shaped refractory bricks is also substantial. This reflects not only industrial production needs but also a pursuit of technological innovation and high-efficiency production.

Traditional refractory bricks, with their standardized shapes and sizes, struggle to meet the requirements of certain specialized industrial environments. Custom-shaped refractories, as the name suggests, can be customized in shape and specifications according to the specific needs of customers. This flexibility allows them to perfectly adapt to various complex industrial furnaces and heat treatment equipment, thereby improving equipment efficiency and lifespan.

Custom-shaped refractory bricks not only reflect technological advancements in the refractory materials industry but also actively respond to the future trend of personalized and refined industrial production. They demonstrate the limitless possibilities that can be created by combining traditional industry with modern technology.

The Advantages of Shaped Refractories at Rongsheng Refractory Factory

Breaking Conventions, Unlocking Diverse Shapes

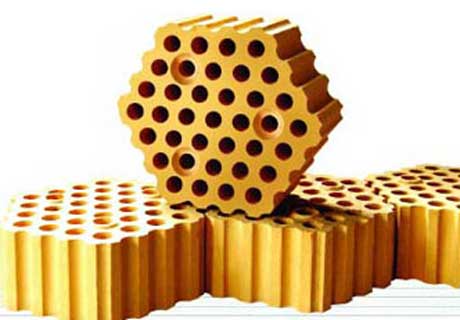

Custom-shaped bricks break free from the constraints of traditional refractory bricks’ regular shapes, appearing in trapezoidal, hexagonal, circular, arc-shaped, and even more complex combinations to meet the needs of various industrial kilns and high-temperature equipment.

In steelmaking furnaces in the metallurgical industry, refractory bricks need to fit tightly into the complex furnace structure. Custom-shaped bricks can be customized according to the special shapes of different parts such as the furnace wall, bottom, and top, ensuring precise protection for every area. In rotary kilns in cement production, custom-shaped bricks can adapt to the curved shape of the cylinder and the special needs of different parts, effectively resisting the erosion of high-temperature materials and flames. The special structure and high-temperature environment of glass melting furnaces also require custom-shaped bricks to achieve efficient heat insulation and protection. These unique shapes make custom-shaped bricks the “close-fitting armor” of industrial high-temperature equipment.

Precise Customization for Complex Working Conditions

Unlike ordinary refractory bricks, the greatest appeal of custom-shaped bricks lies in their ability to be personalized to meet specific customer needs. From size and material formulation to appearance and performance indicators, every detail is precisely controlled.

For chemical corrosion in high-temperature environments, custom-shaped bricks with special components can be customized to enhance their resistance to corrosion. In environments with frequent thermal shock, optimized materials and structures improve the thermal shock resistance of custom-shaped bricks, ensuring stability even under drastic temperature changes. When equipment has extremely high sealing requirements, the precise dimensions and tight joints of custom-shaped bricks effectively prevent the leakage of high-temperature gases and liquids. This high degree of customization allows custom-shaped bricks to perform optimally in various complex working conditions, safeguarding industrial production.

Precise Customization for Complex Working Conditions

Unlike ordinary refractory bricks, the greatest appeal of custom-shaped bricks lies in their ability to be personalized to meet specific customer needs. From size and material formulation to appearance and performance indicators, every detail is precisely controlled.

For chemical corrosion in high-temperature environments, custom-shaped bricks with special components can be customized to enhance their resistance to corrosion. In environments with frequent thermal shock, optimized materials and structures improve the thermal shock resistance of custom-shaped bricks, ensuring stability even under drastic temperature changes. When equipment has extremely high sealing requirements, the precise dimensions and tight joints of custom-shaped bricks effectively prevent the leakage of high-temperature gases and liquids. This high degree of customization allows custom-shaped bricks to perform optimally in various complex working conditions, safeguarding industrial production.

Widely applied, it protects industrial high temperatures

The presence of custom-made special-shaped bricks is widely seen in high-temperature equipment in numerous industries such as metallurgy, chemical engineering, power, and building materials, becoming a key force in ensuring the stable operation of industrial production.

In the metallurgical industry, from blast furnaces for ironmaking to converters for steelmaking, custom-made special-shaped bricks provide reliable refractory protection for the smelting process of high-temperature molten metals, enhancing production efficiency and equipment safety. In the field of chemical engineering, in the reaction furnaces and high-temperature pipelines of fertilizer plants and chemical plants, special-shaped custom bricks can resist the erosion of corrosive gases and liquids, ensuring the smooth progress of the production process. In the power industry, power plants and substations use custom-made special-shaped bricks to insulate against high temperatures and ensure the safe operation of electrical equipment. In the building materials industry, ceramic kilns, glass kilns and cement kilns, as well as custom-made special-shaped bricks, are subject to the erosion of high-temperature flue gas and materials, ensuring the long-term stable operation of the kilns.

Refractory material special-shaped refractories, with their unique shapes, personalized customization services, exquisite production techniques and wide application fields, have demonstrated strong capabilities in the industrial high-temperature field. With the continuous advancement of industrial technology and the increasing demand for high-temperature protection, the demand for special-shaped custom bricks will gradually increase. Of course, customizing special-shaped refractory bricks is no easy task. It requires close cooperation among customers, designers and manufacturers. Customers need to clearly define their specific usage environment and performance requirements. Designers should carry out precise designs based on these demands, while manufacturers must possess a high level of production capacity and technical strength to complete this complex customization process. Rongsheng Refractory Factory, with its advanced technology and production process, can customize special-shaped Refractory brick products for you. Contact Rongsheng Refractory Factory to obtain free samples and quotations.

Specialized manufacturer of special-shaped refractory bricks for the foundry industry

The main special-shaped refractory brick products of the shaped refractory materials manufacturer are as follows:

Pouring cup

The gate cup is a funnel-shaped outer gate, either manufactured separately or formed directly within the mold, serving as an expanded part of the top of the sprue. Its function is to receive the molten metal from the ladle, prevent splashing and overflow, and facilitate pouring. Reduce the direct impact of molten metal on the mold; It is possible to skim off some of the slag and impurities and prevent them from entering the sprue. Increase the static pressure of the molten metal. The sprue cups are divided into two types: funnel-shaped sprue cups and sprue basins. The funnel-shaped spout cup has a simple structure and saves metal, but its skimming effect is poor. To remove the residue, it is usually used in combination with a filter screen.

Ceramic runner for casting

Ceramic gating products for casting are suitable for molding processes such as resin sand, sodium silicate sand, and coated sand, and are used for casting high manganese steel, alloy steel, carbon steel, high chromium cast iron, ductile iron, gray iron and other castings. Ceramic runner pipes introduce ceramic products into the field of refractory materials. The diversification of ceramic forming processes enriches the design of gates, and the distribution of molten metal is more meticulous and reasonable.

Flow Steel Brick

Flow steel bricks refer to hollow refractory bricks built in the grooves of the base plate for ingots to connect the steel bricks and the steel ingot molds, commonly known as channel bricks. To reduce the resistance during the flow of molten steel and prevent steel leakage, it is required that the inner holes of the flow steel bricks be smooth, their shapes be regular, and the joints be tight. Flow steel bricks, as the channel for molten steel to enter the ingot mold from the ladle, play a very crucial role in the steel casting operation by the drop method. On the one hand, the flow steel bricks should be able to ensure the safety of the casting process, preventing accidents such as steel leakage caused by the cracking of the channel bricks, and guaranteeing the safety and smooth flow of the ingot casting operation. On the other hand, it should have good anti-erosion and anti-melting loss performance, without causing melting loss and spalling of refractory materials during casting, to avoid reducing the entry of refractory materials into molten steel and becoming inorganic non-metallic inclusions in future steel products, so as to ensure the quality of steel products.

Riser

A riser is a supplementary part added to the top or side of a casting to prevent defects. In a mold, the cavity of a riser is an empty space for storing liquid metal. When the casting is formed, metal is replenished to prevent shrinkage cavities, porosity, exhaust and slag accumulation. The main function of the riser is to replenish shrinkage. The design functions of risers vary. Different risers have different forms, sizes and positions for installation.

Low creep high alumina checker bricks for hot blast stoves