Insulating Fire Brick for sale in Rongsheng Kiln Refractory is a kind of firebrick that made from high-purity refractory clays with graduated additions of alumina for the higher temperature-rated products and is mainly used for insulating layer of kiln and furnace to prevent the temperature losing.

Description for Insulation Fire Brick

Insulating firebrick for sale is a kind of refractory insulation materials and has up to 1850 ℃ refractoriness. Its chemical and physical properties serve the purpose of all kinds change in the heating furnace.

Mullite Bricks

Lightweight Silica Insulation Bricks

Light Weight Fire Clay Insulation Brick

Kiln Fire Bricks for Sale

Alumina Bubble Brick

Medium Duty Firebrick For Sale

Classification of Insulating Fire Brick

- Light Weight Fire Clay Insulation Brick

- High Alumina Insulation Refractory Brick

- Mullite Insulation Fire Brick

- Alumina Bubble Brick

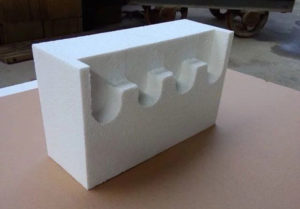

Mullite Insulation Fire Brick

Mullite insulation brick is manufactured with tiny air space similar to honeycomb and the bricks have an excellent insulating property. Mullite insulating bricks can be used in industrial furnace and kilns such as for hot face furnace lining or outer back-up heat lining insulation with features of resisting high temperature and saving heat energy efficiently.

Light Weight Fire Clay Insulation Brick

Fire Clay Insulation Brick can be used in melting furnace, refine equipments, heating equipment, regenerative apparatus, gas furnace, soaking pit, annealing furnace, reaction chamber and other industrial hot working equipment with xcellent performance of high strength, even bulk density, low thermal conductivity and low impurity.

High Alumina Insulation Refractory Brick

High Alumina Insulation Refractory Bricks are mainly used to construct and protect linings of Blast Furnace, Hot Air Furnace, Air Furnace, Reverberatory Furnace and Rotary kiln and etc with high temperature strength, high thermal stability and good chemical slag erosion resistance.

Alumina Bubble Brick

Alumina Bubble Brick is a quality refractory material for resisting high temperature and special demands of positions for furnace and kiln and can be used for service linings in manufacturing high-purity quartz for the electronics industry.

Performance of Insulating Fire Brick

- Good insulation values

- High strength

- Lower content of iron and other impurities

- Lower heat storage

- Low reheat shrinkage

- Low heat conductivity

- High cold crushing strength

- Resistance to CO erosion

- High temperature resistance

- Good temperature shock resistance

Application of Insulating Fire Brick

- Insulation firebrick is mainly use for all kinds of linings, such as

- Blast furnace for iron-making.

- Hot blast stove for chemical industry.

- Rotary kiln for cement-making, chemical metallurgical and lime-making.

- Heating furnace & Power boiler & Lime kiln

Technical Index of Insulating Fire Brick

Fireclay Insulation Brick

| Item/Index | Unit | Fireclay Insulation Brick | |||

| NG-0.6 | NG-0.8 | NG-1.0 | NG-1.3 | ||

| Al2O3 ≥ | % | — | — | — | — |

| Fe2O3 ≤ | % | — | — | — | — |

| Bulk Density ≤ | g/cm3 | 0.6 | 0.8 | 1.0 | 1.3 |

| Cold Crushing Strength ≥ | MPa | 1.5 | 2.5 | 3.0 | 4.5 |

| Reheating Linear Change (Testing Temperature ≤ 2%) | ℃ | 1200 | 1250 | 1350 | 1350 |

| Thermal Conductivity (Average Temperature 350℃±25℃) | W/M*K | 0.25 | 0.35 | 0.5 | 0.60 |

High Alumina Insulation Brick

| Item/Index | Unit | High Alumina Insulation Brick | ||

| LG-0.6 | LG-0.8 | LG-1.0 | ||

| Al2O3 ≥ | % | 48 | 48 | 48 |

| Fe2O3 ≤ | % | 2.0 | 2.0 | 2.0 |

| Bulk Density ≤ | g/cm3 | 0.6 | 0.8 | 1.0 |

| Cold Crushing Strength ≥ | MPa | 2.0 | 3.0 | 4.0 |

| Reheating Linear Change (Testing Temperature ≤ 2%) | ℃ | 1350 | 1400 | 1400 |

| Thermal Conductivity (Average Temperature 350℃±25℃) | W/M*K | 0.3 | 0.35 | 0.5 |

Mullite Insulation Fire Brick

| Item/Index | Unit | Mullite Insulation Fire Brick | |||

| LG-0.6 | LG-0.8 | LG-1.0 | |||

| Al2O3 ≥ | % | 63 | 65 | 65 | |

| Fe2O3 ≤ | % | 0.8 | 0.8 | 0.8 | |

| Bulk Density ≤ | g/cm3 | 0.6 | 0.8 | 1.0 | |

| Cold Crushing Strength ≥ | MPa | 1.5 | 3.0 | 2.5 | |

| Reheating Linear Change 1450℃*12h

/1500℃*12h ≤ |

% | 1.5 | 1.0 | 1.0 | |

| % | — | — | — | ||

| 0.1Mpa Refractoriness Under Load To.6 RUL ≥ | ℃ | 1300 | 1400 | 1450 | |

Alumina Bubble Brick

| Item/Index | Unit | Alumina Bubble Brick | |

| BG-1.2 | BG-1.4 | ||

| Al2O3 ≥ | % | 80 | 80 |

| Fe2O3 ≤ | % | 0.5 | 0.5 |

| Bulk Density ≤ | g/cm3 | 1.25 | 1.45 |

| Cold Crushing Strength ≥ | MPa | 6 | 8 |

| Reheating Linear Change 1450℃*12h

/1500℃*12h ≤ |

% | — | — |

| % | 0.5 | 0.5 | |

| 0.1Mpa Refractoriness Under Load To.6 RUL ≥ | ℃ | 1550 | 1600 |

Insulating Fire Brick Supplier

Rongsheng is one of professional insulation bricks suppliers and export all kinds of high quality insulation firebrick for sale at lower price such as high alumina insulation refractory bricks, silica insulation bricks, lightweight silica insulation bricks, calcium silicate insulation bricks and etc. Rongsheng has professional sales team and engineers to provide customers with professional advice on application of all kinds of insulating refractory brick and also customize insulating firebrick for sale according to your special requirements for shapes and sizes.

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: