Cement plants use low cement castables with a working temperature of 1300°C. Under the high-temperature state of low cement castable, the strength can reach more than 60MPa. At about 1300°C, the strength of the low-cement castable lining can reach more than 60MPa, which is also a remarkable feature of the low-cement castable at high temperatures. Therefore, it can be used as a furnace lining in the high-temperature zone of the cement plant with an operating temperature of 1300 °C.

Physical and Chemical Indicators of Low Cement Castables

Low-cement castables are made of refractory materials such as bauxite, brown corundum, and silicon carbide, and are formulated with ultra-fine powder technology and high-dispersion technology. Low cement content, high strength after burning, and no decrease in medium temperature strength. It has good construction fluidity, volume stability, and certain wear resistance. Low cement castable with a working temperature of 1300℃.

-

DL-60 low cement castable

- Applicable parts: small and medium-sized aluminum smelting furnaces, furnace tops of holding furnaces, and other working linings that do not contact molten aluminum.

- Product type: high aluminum base low cement castable.

- Operating temperature: The highest operating temperature is 1350°C.

- Main ingredients: calcined aluminum clay as the main material.

- Product packaging: paper-plastic composite packaging 25kg/bag, heat-shrinkable wooden pallet 1050kg/pallet.

- Shelf life: 6 months under a suitable environment.

- Construction method: forced stirring and vibration molding.

- Large particles: 10mm.

- Mixing water volume: 6kg clean water/100kg of this product.

- Main features: high strength, good thermal shock resistance, and good integrity.

- Physical and chemical indicators:

| Chemical Composition | Bulk Density | Compressive Strength | Permanent Liner Change Rate | |

| AL2O3 | CaO2 | g/cm³ | Mpa ≥ | % ≤ |

| ≥ % | ≤ % | ≥ | 1000℃X3h | 1000℃X3h |

| 60 | 2.5 | 2.5 | 60 | 0.3 |

-

DL-70 low cement castable

- Applicable parts: Medium-sized aluminum smelting furnaces, furnace tops of holding furnaces, and other working linings that do not contact the molten aluminum.

- Product type: high aluminum base low cement castable.

- Operating temperature: The highest operating temperature is 1350°C.

- Main ingredients: Calcined bauxite is the main material.

- Product packaging: paper-plastic composite packaging 25kg/bag, heat-shrinkable wooden pallet 1050kg/pallet.

- Shelf life: 6 months under a suitable environment.

- Construction method: forced stirring and vibration molding.

- Large particles: 10mm.

- Mixing water volume: 6kg clean water/100kg of this product.

- Main properties: high strength, good thermal shock resistance, and good integrity.

- Physical and chemical indicators:

| Chemical Composition | Bulk Density | Compressive Strength | Permanent Liner Change Rate | |

| AL2O3 | CaO2 | g/cm³ | Mpa ≥ | % ≤ |

| ≥ % | ≤ % | ≥ | 1000℃X3h | 1000℃X3h |

| 70 | 2.5 | 2.6 | 60 | 0.3 |

-

DL-75 low cement castable

- Applicable parts: medium and large aluminum smelting furnaces, furnace tops of holding furnaces, and other working villages that do not touch the molten aluminum.

- Product type: high aluminum base low cement castable.

- Operating temperature: The highest operating temperature is 1450°C.

- Main ingredients: burnt aluminum clay as the main material.

- Product packaging: paper-plastic composite packaging 25kg/bag, heat-shrinkable wooden pallet 1050kg/pallet.

- Shelf life: 6 months under a suitable environment.

- Construction method: forced stirring and vibration molding.

- Large particles: 10mm.

- Mixing water volume: 5kg clean water/100kg of this product.

- Main performance: It is bonded with high-purity aluminate cement. High refractoriness, high strength, anti-stripping, good wear resistance, and good integrity.

- Physical and chemical indicators:

| Chemical Composition | Bulk Density | Compressive Strength | Permanent Liner Change Rate | |

| AL2O3 | CaO2 | g/cm³ | Mpa ≥ | % ≤ |

| ≥ % | ≤ % | ≥ | 1000℃X3h | 1000℃X3h |

| 72-76 | 2.0 | 2.65 | 70 | 0.2 |

-

DL-80 low cement castable

- Applicable parts: aluminum smelting furnace, furnace roof, furnace wall, and other working linings that do not contact molten aluminum.

- Product type: high aluminum base low cement castable.

- Operating temperature: The highest operating temperature is 1500°C.

- Main ingredients: Calcined bauxite is the main material.

- Product packaging: paper-plastic composite packaging 25kg/bag, heat-shrinkable wooden pallet 1050kg/pallet.

- Shelf life: 6 months under a suitable environment.

- Construction method: forced stirring and vibration molding.

- Large particles: 10mm.

- Mixing water volume: 5kg clean water/100kg of this product.

- Main performance: It is bonded with high-purity aluminate cement. Excellent material selection, high refractoriness, high strength, anti-stripping, good wear resistance, and good integrity.

- Physical and chemical indicators:

| Chemical Composition | Bulk Density | Compressive Strength | Permanent Liner Change Rate | |

| AL2O3 | CaO2 | g/cm³ | Mpa ≥ | % ≤ |

| ≥ % | ≤ % | ≥ | 1000℃X3h | 1000℃X3h |

| 78-82 | 2.0 | 2.8 | 80 | 0.2 |

-

DL-90 low cement castable

- Applicable parts: aluminum smelting furnaces, holding furnaces, and other working linings that require high strength and wear resistance.

- Product type: Corundum-based low cement castable.

- Operating temperature: The highest operating temperature is 1600°C.

- Main ingredients: Brown corundum is the main material.

- Product packaging: paper-plastic composite packaging 25kg/bag, heat-shrinkable wooden pallet 1050K9/pallet.

- Shelf life: 6 months under a suitable environment.

- Construction method: forced stirring and vibration molding.

- Large particles: 5mm.

- Mixing water volume: 4kg clean water/100kg of this product.

- Main performance: It is prepared from high-grade raw materials. High refractoriness, high strength, good peeling resistance, good wear resistance, good integrity, and stable volume.

- Physical and chemical indicators:

| Chemical Composition | Bulk Density | Compressive Strength | Permanent Liner Change Rate | |

| AL2O3 | CaO2 | g/cm³ | Mpa ≥ | % ≤ |

| ≥ % | ≤ % | ≥ | 1000℃X3h | 1000℃X3h |

| 88-92 | 2.0 | 3.0 | 90 | 0.1 |

Refractoriness of Low Cement Refractory Castables

The refractoriness of low-cement refractory castables is greater than 1790°C, and the load softening temperature (4% deformation) at 0.2MPa is 20-100°C higher than that of CA50 cement refractory castables. Therefore, the service temperature of low-cement refractory castables is generally about 100°C higher than that of CA50 cement refractory castables of the same material.

What is the working temperature of low cement castables? The service temperature of low-cement castables is higher than that of ordinary refractory castables of the same material.

Clay-based and high-alumina low-cement castables are used for the lining of various heat treatment furnaces such as heating furnaces and soaking furnaces and rotary kilns linings. Mullite low-cement castables are used for various high-temperature burner linings, heating furnace water-cooled pipe wrapping linings, etc. Corundum and chromium-containing corundum low-cement castables are used for the lining of some parts of the refining device outside the molten steel furnace and are also used for the lining of power frequency induction furnaces for lining petrochemical catalytic cracking reactors for high-temperature wear-resistant linings, etc. Al2O3-SiC-C low-cement castables are used as linings for blast furnace tapping troughs, iron melting furnace tapping troughs, integral powder spraying guns for molten iron pretreatment, etc.

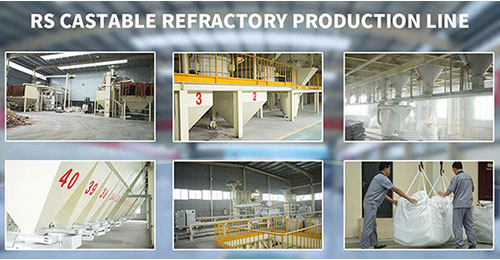

Rongsheng Kiln Refractory Manufacturer

Rongsheng Kiln refractory material manufacturer is a manufacturer and seller of refractory castables with rich production and sales experience. Our refractory products have been sold to more than 70 countries and regions all over the world. And received recognition and praise from customers. Whether it is refractory bricks or monolithic refractory castable products, we can customize them according to the needs of high-temperature industrial furnaces. For the design and construction of various rotary kiln insulation layer refractory materials, please contact us, we can provide free samples and quotations.

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: