Refractory material is a kind of inhomogeneous body, which is composed of solid matter (solid phase), including crystalline phase and amorphous phase, and pores (gas phase). The shape, size, quantity, arrangement, distribution, and combination of solid phase and gas phase are called the macroscopic structure of refractory material. It characterizes the density and uniformity inside the refractory material. It reflects the structural characteristics of refractory material, including porosity, water absorption, bulk density, true density, and air permeability. Refractory density.

Bulk Density

Bulk density, abbreviated as B.D. or BD, refers to the ratio of the mass of the dry product to the total volume. That is, the mass of the material per unit volume (including pores), expressed in g/cm³.

Bulk density is the main indicator of the compactness of the product. When the density is high, it can reduce the total area of the external intrusion medium (phase or gas phase) acting on the refractory material, thereby increasing the service life. However, in the production of lightweight insulation products, in order to reduce the heat capacity and thermal conductivity, people use various means to reduce the bulk density of the product.

Density of Refractory Materials

The presence of pores in refractory materials affects the porosity, water absorption, bulk density, air permeability, and other indicators of refractory materials. By measuring the mass of the sample and then determining its volume by liquid static weighing, the apparent porosity, bulk density, and water absorption can be calculated. Refractory density, the density of refractory materials, varies depending on the type of material, production process, and other factors. The following are the density ranges of some common refractory materials:

- Ordinary clay brick: 1.8~2.0g/cm³

- Dense clay brick: 2.05~2.20g/cm³

- High-density clay brick: 2.25~2.30g/cm³

- Silica brick: 1.80~1.95g/cm³

- Magnesium brick: 2.60~2.70g/cm³

- Magnesium-calcium brick: ≥2.95g/cm³

- Sin-bonded sic for blast furnace: ≥2.58g/cm³

- High-alumina brick: ≤22g/cm³

- Stability dolomite brick: about 2.83g/cm³

- Semi-rebonded magnesia-chrome brick: 2.10g/cm³

- Directly bonded magnesia-chrome brick (mgo82.6 1%, cro8.72%): 3.08g/cm³

- Fused corundum brick (alo>93%): 3.54g/cm³

- Fused zirconium mullite brick: 2.85~2.95g/cm³

- Fused zirconium oxide brick (zro94%): >5.35g/cm³

- Fused magnesia chrome brick (mgo50%~60%, cro15%~20%): >3.7g/cm³

- Corundum rebonded brick (alo>98%): 2.95g/cm³

- Sintered corundum brick (alo>98.5%): 2.95g/cm³

- Zirconium corundum brick (azs33, azs40): 1g/cm³

- Silicon carbide brick for blast furnace (sin, sialon, β-sic bonded): 2.60~2.9g/cm³

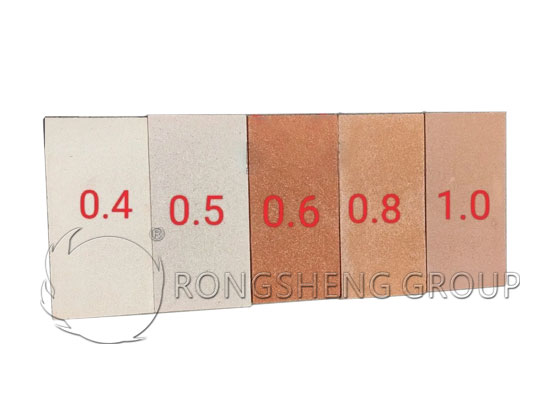

The Density of Lightweight Clay Insulation Bricks is between 0.4-1.2. What is the Difference?

In the field of high-temperature industry, lightweight clay insulation bricks are commonly used as refractory materials. With their heat insulation and light weight, they effectively guarantee the operation of equipment and save energy. The density of this type of insulation brick is commonly found in the range of 0.4, 0.5, 0.6, 0.8, 1.0, 1.2 (unit: g/cm³). Products with different densities have significant differences in refractory performance and structural strength. The key difference between these lightweight clay insulation bricks of different densities as refractory materials!

Refractory Temperature: The Relationship between Density and High Temperature Resistance

Refractory temperature is the core indicator for measuring the performance of refractory materials. Generally speaking, in the density range of 0.4 – 1.2g/cm³, lightweight clay insulation bricks with higher density have better refractory performance. Insulation bricks with a density of 1.0 – 1.2g/cm³ have a tighter internal structure and a more uniform distribution of mineral components. They can maintain a stable crystal structure at high temperatures and can usually withstand high temperatures of 1200℃ – 1300℃. They are suitable for extremely high temperature parts such as rotary kiln linings and boiler high temperature sections.

Insulation bricks with a density of 0.4 – 0.6g/cm³ have large internal porosity and relatively loose structure, and are prone to problems such as uneven thermal expansion and pore collapse at high temperatures. Their refractory temperature is mostly around 900℃ – 1100℃. They are more suitable for auxiliary insulation areas with relatively low temperatures, such as the outer insulation layer of industrial furnaces.

Thermal conductivity: How density affects insulation efficiency

As a refractory material, insulation efficiency is directly related to the energy consumption of the equipment. Low-density lightweight clay insulation bricks (such as 0.4 – 0.6g/cm³) have a large number of pores inside to form an air insulation layer, and the thermal conductivity is usually 0.1 – 0.2W/(m·K). It can effectively prevent heat transfer, reduce heat loss on the surface of the equipment, and reduce energy consumption. For example, using low-density insulation bricks on the outer layer of a metallurgical heating furnace can significantly reduce the surface temperature of the furnace and improve energy utilization.

As the density increases to 0.8 – 1.2g/cm³, the internal pores of the insulation bricks decrease, and the thermal conductivity rises to 0.2 – 0.4W/(m·K). Although its thermal insulation performance is not as good as that of low-density products, its relatively stable structure makes it more suitable for parts that need to be insulated and withstand a certain high temperature impact in a high temperature environment. Such as the middle insulation layer of a heating furnace.

Mechanical strength: Density determines load-bearing and impact resistance

In high-temperature industrial environments, refractory materials need to withstand external forces such as mechanical vibration and material scouring. Lightweight clay insulation bricks with higher density (0.8 – 1.2g/cm³) have a compressive strength of 3 – 8MPa and a flexural strength of 1 – 2MPa because the internal particles are tightly bound, which can better resist mechanical external forces and thermal stress shocks. They are suitable for use in load-bearing parts of industrial kilns, linings of material conveying channels and other areas susceptible to wear.

Insulation bricks with a density of 0.4 – 0.6g/cm³ have weaker mechanical strength and a compressive strength of only 1 – 3MPa. They are prone to cracking and peeling when subjected to large external forces or frequent thermal expansion and contraction. Therefore, they are more suitable as non-load-bearing insulation materials, such as the outer insulation wrapping layer of high-temperature equipment.

Chemical stability: corrosion resistance performance of different densities

Under high temperature conditions, refractory materials are often exposed to chemical corrosion (such as acid and alkali gas, melt penetration, etc.). Lightweight clay insulation bricks with higher density can effectively block the penetration of chemical substances due to their dense structure and low porosity (usually 45% – 60%). In environments with chemical corrosion such as glass kilns and chemical reactors, the corrosion resistance is stronger.

In contrast, insulation bricks with lower density (porosity can reach 70% – 85%) are more likely to be penetrated by chemical substances through pores, resulting in deterioration of material performance. Therefore, they are not suitable for strong chemical corrosion environments, but are more suitable for ordinary high-temperature insulation scenarios with lower requirements for chemical stability.

Comparison of Actual Application Scenarios

Lightweight clay insulation bricks of different densities have their own strengths in the field of refractory materials. When choosing, it is necessary to make a comprehensive judgment based on factors such as temperature, chemical environment, and mechanical load of specific working conditions. Only by accurately matching density with application requirements can the performance advantages of insulation bricks be fully utilized to improve the safety and service life of high-temperature equipment!

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: