Refractory plastics are used as unshaped refractory materials. Plastics refractory have good heat and shock resistance and are easy to construct. It is suitable for the roof, wall, cover, and other parts of industrial furnaces such as various heating furnaces, soaking furnaces, annealing furnaces, hot blast furnaces, etc. It can also be used for small electric arc furnace cover, high-temperature furnace burner, and other parts, as well as partial repair of furnace lining and covering protection of certain metal parts. The main reason why High-Temperature Refractory Plastics are widely used is the continuous furnace, hot repair, and quick drying.

Use Temperature of Refractory Plastics

The main raw materials of High-Temperature Refractory Plastics are refractory aggregates and powders, raw clay, chemical composite binders, and admixtures. It is an unshaped refractory that has good plasticity after being mixed, packaged, and stored for a certain period of time, and can be constructed by tamping. The plastic material is especially suitable for furnaces such as heating furnaces, soaking furnaces, annealing furnaces, sintering furnaces, and boilers. The use temperature of refractory plastics depends on the quality of the material. Common refractory plastics can be used at 1300-1400°C, and some plastics can be used at temperatures of 1400-1500°C. Corundum plastic can be used for temperatures of 1600-1700℃, and high wear-resistant plastic can be used for the furnace of a boiler.

Corundum wear-resistant plastics are made of high alumina bauxite clinker, corundum, and silicon carbide, and other wear-resistant raw materials like aggregates, combined with powder or liquid binder, and mixed with several additives. It is a kind of plastic with excellent abrasion resistance at high temperatures. It is suitable for the cyclone cylinder, furnace wall lining, and parts with severe impact and wear of coal ash of circulating fluidized bed boiler. Often these parts need to be hotly repaired without stopping the furnace. The only refractory material that can quickly repair the furnace and repair the furnace is the rapid repair furnace type refractory plastic.

Precautions for High-Temperature Refractory Plastics

Under normal circumstances, plastics refractory do not use hydraulic binders. Even if the air-hardening agent is used, sealing measures should be taken during storage. If the plastic material has high water content, the plastic material will lose its hardness as the moisture is lost. Therefore, High-Temperature Refractory Plastics should be retarded.

Refractory plastics, because there is no chemical bond added, will change in strength with increasing and decreasing temperature changes. During the construction of the plastic, the appropriate drying speed should be controlled so that cracks are not easy to occur. If it is used on the roof of a large kiln, sodium silicate must be added and the mold can be removed quickly after construction.

The thermal shock resistance of plastics is better than that of castables of the same material, so it can be used in places with high-temperature fluctuations. Especially after the construction of the furnace roof and the furnace wall is completed during emergency repairs, there is no need to bake, and the strength of the plastic can be increased directly as the furnace temperature rises. Refractory plastic does not require special skills during the construction. At the beginning of construction, take out the plastic material directly from the sealed bag and spread it between the hanging brick and the hook. The general construction thickness is 50-70mm. Use a wooden hammer or air hammer to tamping in layers to form the required shape of the part. When the plastic is not hardened, use a tool to squeeze out the remaining material to repair the shape. After repairing, vent holes at regular intervals and leave expansion joints to drain the water.

How to Efficiently Carry Out Refractory Plastics Construction?

The quality of High-Temperature Refractory Plastics is important, and construction technology is more important. The construction is not good, no matter how good the quality of fire-resistant plastic is, it is useless.

High-Temperature Refractory Plastics must first be sealed well to retain moisture. Before the fire-resistant plastic is rammed, check the anchor brick for cracks. After the fire-resistant plastic is rammed, there are at least three to four days for natural drying.

For plastic ramming, a template should be used. The support mold depends on the specific situation of the site. The template with a large area should be movable. The construction surface is 5-10mm more than the bottom surface of the anchor brick. The formwork must have a certain strength to prevent displacement during the construction process. The gap between the end face of the anchor brick and the furnace roof template is 4-6mm, and it cannot be greater than 10mm after ramming.

If the refractory plastic is bulk material, the thickness of each layer is 100mm. When ramming the furnace wall and furnace roof, the direction should be parallel to the heating surface. When ramming the furnace bottom, the direction can be perpendicular to the heating surface. Only one blank can be placed on each layer. If there is a triangle seam, when ramming the outer edge, make the ramming hammer slightly tilt and chamfer, so that one layer of blank and the previous layer are bonded together. However, the impact force on the ram should be limited so that the top surface of the blank cannot be piled up.

The anchor bricks should be placed so that the two deeper corrugated surfaces are perpendicular to the top surface of the refractory plastic. Knock the anchor brick gently into the plastic blank. The anchor brick and the plastics must be fully combined. After the anchor bricks are fixed, a plastic blank is placed between the two anchor bricks, and then rammed to both sides to make the anchor bricks filled.

High-Temperature Refractory Plastics construction can be carried out continuously. If construction is interrupted, cover the tamped plastic with a plastic sheet. When the construction is interrupted for a long time, the joints should be left at the centerline of the same row of anchor bricks or hanging bricks. When ramming continues, shave the rammed refractory plastic surface. When the temperature is high, moisten the surface before ramming.

High-Temperature Refractory Plastics expansion joints shall be set according to design requirements. The expansion joints of the furnace wall and roof must be in a straight line. Leave horizontal expansion joints and vertical expansion joints at the junction. Fill the expansion joint with refractory fiber and then ramming.

Rongsheng refractory plastic manufacturer

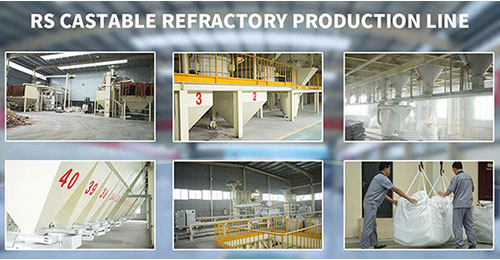

Rongsheng is a kiln refractory manufacturer with an advanced and fully automatic unshaped refractory production line. Rongsheng’s monolithic refractory capacity can produce 80,000 tons per year. It has unique advantages in the formulation of various refractory castables. At the same time, we can also provide customers with various high-quality High-Temperature Refractory Plastics, refractory ramming mix materials, refractory mortar, etc. according to the working conditions of the refractory linings of different industrial kilns. If your industrial furnace lining needs to be repaired, perhaps refractory plastic is a good choice.

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: