The installation method of ceramic fiber modules directly impacts the insulation, sealing, and service life of industrial furnace linings. Depending on module size and furnace structure, parallel and patchwork installations are primarily used. RS Kiln Refractory Factory provides a systematic introduction to these modules, including their definition, characteristics, installation steps, and applicable scenarios.

What are the Ceramic Fiber Modules?

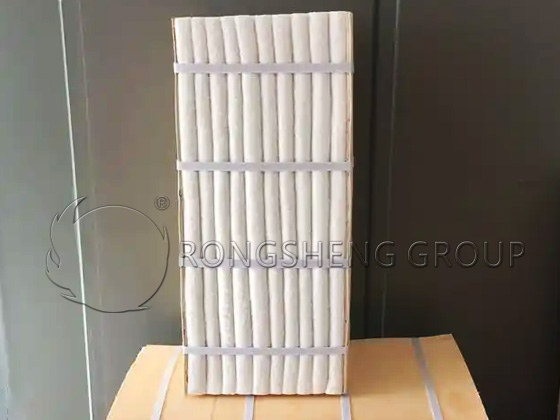

Ceramic fiber modules are mechanically folded and cut to precise dimensions.

Using a polymer sheet and strapping for compression and fixation, ceramic fiber modules achieve precise dimensions and facilitate installation.

Carton packaging offers an aesthetically pleasing appearance, effectively protects the fiber module surface, and improves the working environment.

Ceramic fiber modules and folding blocks are available in a variety of structural styles, including angle iron, butterfly, hanging, diamond, herringbone, hook, and corner. We can provide users with the optimal module structure based on different furnace types and application conditions.

Ceramic Fiber Module Installation Steps

-

Rust Removal

Before construction, the steel structure contractor must remove rust from the furnace wall steel plates to ensure they meet welding requirements.

-

Wiring

Arrange the ceramic fiber modules according to the design drawings. Lay out lines on the furnace wall plates and mark the locations of the anchor bolts at the welding points.

-

Welding Bolts

According to the design specifications, weld bolts of the appropriate length to the furnace wall plates according to welding requirements. Protect the bolt threads during welding to prevent welding slag from splashing onto the bolt threads and ensure weld quality.

-

Flat Blanket Installation

Lay the first layer of fiber blanket, followed by the second. The joints between the first and second blankets should be staggered by at least 100mm. For ease of installation, the furnace roof flattening should be temporarily secured with snap-on clips.

-

Module Installation

-

- Tighten the guide sleeve into place.

- Align the module’s center hole with the guide sleeve on the furnace wall. Push the module evenly and perpendicularly into the furnace wall until it rests firmly against the wall. Then, use a socket wrench to guide the nut along the guide sleeve to the bolt and tighten it.

- Repeat this process for the remaining modules.

-

Compensation Blanket Installation

Modules are arranged sequentially in the same direction of folding and compression. To prevent gaps between modules due to fiber shrinkage after high-temperature heating, compensation blankets of the same temperature rating must be placed in the non-expansion direction of both rows to compensate for module shrinkage. The wall compensation blankets are secured by the compression of the modules, while the roof compensation blankets are secured with U-shaped nails.

-

Furnace Lining Finishing

After the entire lining is installed, remove the plastic tube from the center of the module and fill the center hole with a cotton blanket. Then, cut the binding tape, remove the wooden boards on both sides, and finish the furnace lining from top to bottom.

-

Flattening

Use a special flat plate to flatten any rough edges and stubble, and flatten and press modules in specific areas to secure them.

-

Furnace Lining Surface Spraying

Apply a layer of surface coating (high-temperature curing agent) to the lining.

How to Eliminate Gaps between Ceramic Fiber Modules?

Ceramic fiber furnace linings, due to their lightweight, thermally insulating, and thermal shock-resistant properties, are gradually replacing traditional heavy refractory bricks as the new mainstream furnace lining. Refractory brick linings use refractory clay to fill the gaps between bricks. How can gaps between refractory fiber modules be eliminated?

Ceramic fiber modules are often installed in a military-style arrangement. There are two types of gaps between modules: longitudinal and width. Ceramic fiber insulation lining.

Compression in the Width

First, the modules have compression resilience in the width direction. After installation, the modules are expanded and compressed by removing the module wrapping tape. This automatically eliminates the gaps in the width direction.

Compensating Blankets Eliminate Row Gaps

Second, compensating blankets are added in the longitudinal direction of the modules, between rows, to compensate for the non-expansion direction of the ceramic fiber modules and eliminate gaps between rows. This is done by folding a ceramic fiber blanket of the same material in half into a U-shape and pressing it tightly to fill the gaps between the rows.

Precise positioning according to the drawing

Precise positioning is also a prerequisite for ensuring the integrity of the ceramic fiber furnace lining. Before installing the ceramic fiber modules, workers will first mark the positioning according to the drawings, weld the module fixing bolts, and rationally plan the distance between each module.

A professional manufacturer of aluminum silicate fiber modules and folding blocks, with a custom processing center for high-temperature resistant thermal insulation parts. We specialize in the production of refractory ceramic fiber modules and aluminum silicate fiber modules, as well as the development of their corresponding applications. We have successfully provided thousands of thermal insulation solutions and materials to hundreds of companies. We are a high-quality supplier of ceramic fiber modules, aluminum silicate modules, and more.

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: