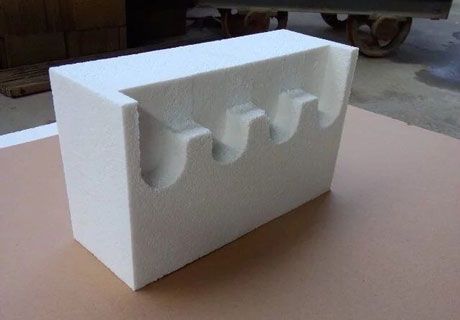

Alumina Bubble Bricks with anti-stripping properties are prepared by using alumina hollow balls, fused corundum powder, α-Al2O3 fine powder, SiO2 fine powder, sillimanite, and fire clay powder as raw materials. As mentioned by “Alumina Bubble Brick“, it has four advantages. How are the advantages of Alumina Bubble Brick formed? As the saying goes, the material foundation determines the superstructure. These are all related to the raw materials used to make Alumina Bubble Bricks and the production method of them.

The Raw Materials of Alumina Bubble Brick

The raw materials of Alumina Bubble Bricks play different roles in the brick making process. Designed to ensure the high performance of Alumina Bubble Bricks.

Alumina hollow ball is light aggregate, it can play the role of high-temperature resistance and reduce density. Corundum powder is an inert filler. Sillimanite is an expansion agent, which plays a role in reducing firing shrinkage and improving thermal shock resistance. Alumina powder, silicon oxide powder, and fire clay powder are binding agents. They can play a role in reducing the sintering temperature, forming a mullite combination phase, and improving the high-temperature resistance and thermal shock resistance of refractory materials.

Production of Alumina Bubble Brick

First of all, according to the set material configuration plan, the raw materials for making bricks are prepared. Then, after kneading, molding, and natural drying for 24h, it is then dried at 110°C for 24h and fired at 1600°C for 4h. Finally, alumina hollow ball insulation bricks were prepared. When the content of sillimanite is 12%, the performance of the alumina hollow ball insulation brick made. It is: bulk density 1.48g/cm3, compressive strength 26 MPa, load softening temperature 1710 ℃, 1600 ℃ x 2h reburning line change + 0.3%, thermal shock resistance (1100 ℃, water cooling) 17 times. Therefore, the alumina hollow ball insulation material has the characteristics of lightweight, high strength, high-temperature resistance, and thermal shock resistance.

Characteristics of Hollow Alumina Balls

The characteristics of hollow alumina balls cannot be ignored either. Alumina hollow ball and its products are a kind of light-weight refractory material with high-temp resistance and excellent energy saving, which are very stable in various atmospheres. It is especially suitable for high-temperature kiln at 1800℃. Hollow spheres can be used as high-temperature, ultra-high-temperature insulation fillers, high-temperature refractory concrete lightweight aggregates, high-temperature castables, etc.

Therefore, alumina bubble bricks can be used in high-temperature energy saving (>30%) inverted flame kiln, shuttle kiln, molybdenum wire furnace, tungsten rod furnace, induction furnace, nitriding furnace, etc. For reducing the weight of the furnace body, transforming the structure, saving materials, and saving energy, obvious results will be achieved.

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: