In today’s industrial landscape, maintaining the integrity and longevity of structures exposed to harsh environments is a critical concern. Whether in chemical plants, refineries, or manufacturing facilities, floors are often subjected to aggressive chemical substances that can quickly degrade conventional construction materials. This is where acid-resistant bricks come into play, offering unparalleled protection and durability. These specialized bricks are not only vital for ensuring safety but also for maximizing the lifespan of industrial flooring.

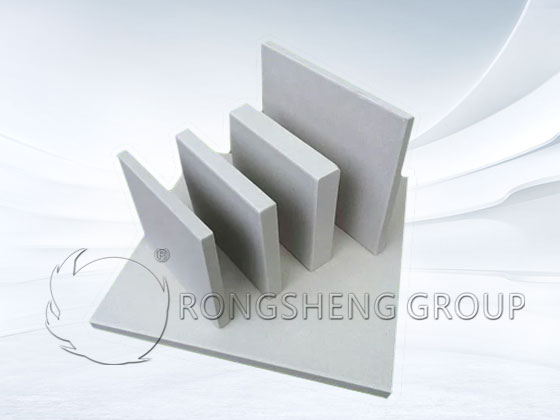

Understanding Acid Resistant Bricks

Acid resistant bricks are a type of brick specifically engineered to withstand corrosive environments, particularly those involving acidic substances. Unlike regular bricks, which can deteriorate when exposed to acids, acid resistant bricks are made from materials that have high chemical durability, such as flint, clay, and other non-metallic materials. They are also fired at high temperatures to enhance their resistance to acids, alkalis, and other aggressive chemicals.

The Critical Role of Acid Resistant Bricks in Industrial Flooring

The role of acid resistant bricks in industrial flooring cannot be overstated. Floors in industrial settings are often exposed to various chemicals, ranging from mild acids to strong alkalis. Without proper protection, these chemicals can seep into the flooring material, leading to corrosion, structural weakness, and eventually, complete failure. Acid resistant bricks serve as a crucial line of defense against such degradation, ensuring that the flooring remains intact and functional for years to come.

1. Enhanced Chemical Durability

One of the primary reasons why acid resistant bricks are indispensable in industrial flooring is their superior chemical durability. These bricks are designed to resist a wide range of chemicals, including sulfuric acid, hydrochloric acid, and nitric acid, among others. This resistance is crucial in industries such as chemical processing, pharmaceuticals, and food and beverage, where spills and leaks are common. By incorporating acid resistant bricks into the flooring design, facilities can prevent chemical damage, reduce maintenance costs, and extend the lifespan of their infrastructure.

2. Corrosion Resistance

Corrosion is a major concern in any environment where chemicals are present. In industrial settings, corrosion can compromise the structural integrity of floors, leading to costly repairs and downtime. Acid resistant bricks play a pivotal role in mitigating this risk. Their ability to resist corrosion from acids and other chemicals makes them an ideal choice for industrial flooring. By preventing corrosion, these bricks help maintain the strength and stability of the floor, ensuring safe and efficient operations.

3. Thermal Stability

Industrial processes often involve high temperatures, which can exacerbate the effects of chemical exposure on flooring materials. Acid resistant bricks are known for their excellent thermal stability, meaning they can withstand both high temperatures and the corrosive effects of acids. This dual resistance makes them particularly suitable for environments where thermal fluctuations are frequent, such as in metal processing or power generation facilities. The use of acid resistant bricks in these settings ensures that the flooring remains resilient, even under extreme conditions.

4. Protective Lining for Concrete Floors

In many industrial applications, acid resistant bricks are used as a protective lining over concrete floors. Concrete, while strong and durable, is susceptible to chemical attack, especially from acids. Over time, acids can penetrate the concrete, causing it to weaken and crack. By installing a layer of acid resistant bricks over the concrete, facilities can effectively shield the underlying structure from chemical damage. This protective lining not only preserves the integrity of the concrete but also enhances the overall durability of the flooring system.

5. Cost-Effective Maintenance

The use of acid resistant bricks in industrial flooring also contributes to cost-effective maintenance. Floors that are protected by these bricks are less likely to suffer from chemical damage, reducing the need for frequent repairs and replacements. Additionally, acid resistant bricks are relatively easy to clean and maintain, further lowering maintenance costs. In the long run, the investment in acid resistant bricks pays off by minimizing downtime, extending the life of the flooring, and reducing the overall cost of ownership.

6. Sustainability and Environmental Impact

In today’s environmentally conscious world, the sustainability of construction materials is a key consideration. Acid resistant bricks are not only durable and long-lasting but also environmentally friendly. Many manufacturers produce these bricks using sustainable practices, such as recycling waste materials and reducing energy consumption during production. Moreover, the longevity of acid resistant bricks means that they do not need to be replaced as frequently as other materials, reducing waste and the environmental impact of industrial operations.

Applications of Acid Resistant Bricks in Industrial Flooring

The applications of acid resistant bricks in industrial flooring are diverse, reflecting the wide range of environments where chemical resistance is essential. Some common applications include:

- Chemical Processing Plants: Where floors are exposed to a variety of aggressive chemicals on a daily basis.

- Pharmaceutical Manufacturing: Where cleanliness and resistance to chemical spills are critical.

- Food and Beverage Facilities: Where acidic substances, such as juices and cleaning agents, can cause damage to conventional flooring.

- Metal Processing Facilities: Where floors must withstand both high temperatures and corrosive chemicals.

- Power Generation Plants: Where acid resistant bricks are used to protect floors from chemical and thermal damage.

RS Acid Resistant Bricks for Sale

In industrial environments where chemical exposure is a constant threat, the importance of acid resistant bricks in protecting and enhancing flooring cannot be overstated. These bricks offer unmatched chemical durability, corrosion resistance, and thermal stability, making them an essential component in the construction of industrial floors. By choosing acid resistant bricks, industries can maximize the lifespan of their flooring, reduce maintenance costs, and ensure the safety and efficiency of their operations. Investing in high-quality acid resistant bricks is not just a smart choice—it’s a critical step toward ensuring the long-term success and sustainability of industrial facilities.

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: