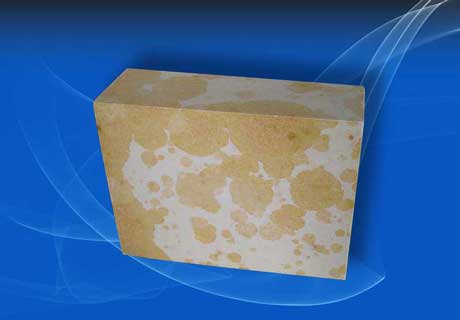

Silica brick undergoes homopolymorphic transformation and volume change during heating. The high deformation temperature under load is an excellent characteristic of silica brick, which is close to the melting point of tridymite and cristobalite (1670 °C, 1713 °C), and fluctuates between 1640 and 1680 °C. The volume of silica brick is stable in the range above 300 °C to close to the melting point (tridymite or cristobalite). During use, when heated to 1450 ℃, about 1.5~2.2% of the total volume expansion, this residual expansion will make the masonry joints close to ensure good airtightness and structural strength of the masonry. The biggest disadvantage of silica brick is the low thermal shock stability, and the heat exchange in water is about 1 to 4 times; followed by the low refractoriness, generally at 1690 to 1730 °C. This limits the scope of its application.

So, why do silica bricks expand? Combining years of production and customer feedback. Rongsheng kiln refractory brick manufacturers summarize the following factors in addition to the expansion of silica bricks.

First, the expansion of silica bricks comes from homogeneous polycrystalline transformation.

SiO2 has seven variants and one amorphous variant at atmospheric pressure. Namely β-quartz, α-quartz, γ-quartz, β-tridymite, α-tridymite, β-cristobalite, α-cristobalite and quartz glass. The transitions between the above variants can be divided into two categories.

- The first category is the transformation between quartz, tridymite, and cristobalite. During the transformation, the original crystal structure must be destroyed (the Si-O bond is dismantled) and a new structure must be reconstituted. That is, the rearrangement of atoms is completed. Due to the large activation energy required, the transition temperature is high and slow, accompanied by large volume effects.

- The second category is the α, β, γ type transitions in the above variants. Since they are very similar in structure and properties, the transition is only structural distortion, and the Si-O bond is not dissociated. Thus, the transition occurs at a certain temperature, the transition is bulky, and it is reversible. The time required to complete the transition between such variants is brief. At the transition temperature, the crystal surface and inside complete the transition instantaneously, and this variant can only coexist at the transition temperature.

Second, the firing expansion of silica bricks.

Silica brick undergoes a phase change during the firing process and has a large volume change. In addition, the amount of solution formed by the brick at the firing temperature is less (about 10%), making it much more difficult to burn than other refractory products. In addition, it is also related to the firing system of silica bricks and a series of physical and chemical changes that occur during the firing process of bricks, the quantity and nature of additions, the shape and size of brick bodies, and the characteristics of firing kilns.

- The physical and chemical changes of silica bricks during the firing process. Silica bricks have the following changes in the order of temperature during the firing process:

-

- Residual moisture is drained from the adobe below 150°C.

- At 450°C, Ca(OH)2 begins to decompose.

- At 450~500 ℃, the dehydration of Ca(OH)2 is completed, the combination of silica particles and lime is destroyed, and the strength of the green body is greatly reduced.

- In the range of 550~650℃, β-quartz is transformed into α-quartz. Due to the volume expansion of 0.82% in the transformation process, microcracks with different densities will appear in the quartz crystal.

- Between 600 and 700 ℃, the solid-phase reaction between CaO and SiO2 begins, and the brick strength increases.

- Starting from 1100°C, the transformation rate of quartz increases greatly, and the specific gravity of adobe also decreases significantly. At this point, the brick volume is greatly increased due to the transformation of the quartz to a low specific gravity variant. Although the liquid phase is also increasing at this time, cracks still occur in the range of 1100~1200℃.

- The volume of siliceous bricks changes during the heating process, which is different at different temperature stages. According to the changing characteristics of various silica bodies, it can be divided into stages below 600°C, 600~1100°C, 1100~1250°C and above 1250°C.

-

- Between 500 and 600 °C, there is a significant expansion due to the β→α type quartz transition.

- At 700~800℃, due to the solid-phase reaction between CaO and SiO2, microscopic shrinkage occurs.

- At 1000~1100℃, the shrinkage is more pronounced due to the formation of the liquid phase.

- Since about 1200 ℃, due to the accelerated transformation of quartz, the green body begins to expand violently, and the starting temperature and rising trend are very different according to the type of raw material.

For more information about silica bricks and high-quality silica bricks, please leave a message on this page or email us directly. We will provide you with the most suitable silica bricks for your production needs according to your specific needs.

Leave Your Requirements on RS Kiln Refractory Bricks And Castable Materials! We Will Reply You In 12 Hours!: